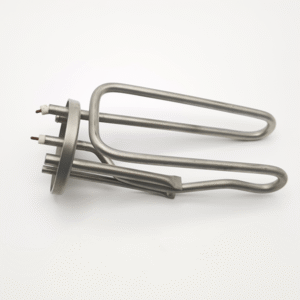

Bundle Rod Heater——High-density bundle rod heating solution

The multi-rod bundle heating element designed for industrial heat treatment furnaces, continuous drying equipment and regional heating systems adopts nickel-chromium alloy (NiCr) + ceramic fiber insulation structure, suitable for 5kW-500kW power range, temperature resistance up to 1200℃ (short time), thermal efficiency ≥95%.

MOQ:1000PCS

Vorlaufzeit:25 Tage

Standort der Fabrik: Zhongshan, Guangdong, China

Home appliances: commercial water boilers, electric water heaters, industrial steam generators, embedded coffee machine heating modules.

Industrial equipment: chemical reactor constant temperature system, food processing high temperature sterilization equipment

Leistungsbereich:

Residential/Commercial: 1.5kW to 15kW (space heater, water heater, HVAC system).

Industrial: 15kW–100kW+ furnaces, dryers, boilers, metalworking tools.

Voltage Compatibility:

global grid compatibility, error ±5%

Material:

Rod material: Incoloy 800 (oxidation-resistant) or high-temperature stainless steel 316L (corrosion-resistant).

Sheath: PTFE-insulated, non-stick, anti-calcification, ceramic-covered.

High-temperature oxidation resistance comes from nickel-chromium (NiCr) alloy or Kanthal (FeCrAl) wire.

Resistance value: 1Ω–50Ω (customizable per voltage/power requirements).

Operating Temperature:

Continuous: 600 °C to 1200 °C (short-term maximum 1500 °C for certain specialized industrial designs).

Dimensions:

Rod length: 100 mm to 3000 mm (flexible bundling options).

Bundle diameter—Φ50mm–Φ200mm—adjustable spacing for heat distribution.

Lifespan:

20,000 to 100,000 hours, varying with temperature, duty cycle, and protective coatings.

High-efficiency heat output

High-Temperature Alloys: Minimal energy loss allows for fast heating (30 seconds to 600 °C).

Uniform Heat Distribution: Reduced hot/cold areas result from bundled design’s guarantee of equal heat spread.

Durability & Safety

Resist oxidation, corrosion, and chemical exposure—perfect for hard applications—ceramic/PTFE coatings.

CE/UL/ATEX certified shut off at >1200°C.

Energie-Effizienz

Fast heating and cooling cycles lower energy waste by means of low thermal mass.

Modular design: change power output for varying loads by adding or removing rods.

Versatile Uses

Industrial: Furnace heating, metal annealing, paint drying, steam generation.

Commercial: HVAC pre-heaters; water heating for restaurants/hotels.

Residential: high efficiency space heaters; underfloor heating systems.

Customizable settings

Alter bundling designs, sheath thickness, and rod spacing to fit particular thermal needs.

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 30 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.

Erhalten Sie in weniger als zwei Tagen ein individuelles Angebot.