Heater heating element

Heizelement für elektrische Heizung

The heating element of the electric heater is the core functional component of the electric heating equipment. It is essentially an “energy converter” that converts electrical energy into thermal energy. Its main body is usually made of resistive materials. Common types include metal wires such as nickel-chromium alloy wire (such as Cr20Ni80), iron-chromium-aluminum alloy (such as 0Cr25Al5), or thick film heating coatings (such as ceramic semiconductors), PTC ceramic sheets and other new materials. The structure is mostly filamentous, sheet-like, tubular or integrated on a substrate (such as an aluminum substrate). The Joule heat is generated by the current flowing through the resistive material, and the heat is directly or indirectly transferred to the target medium (water, air, liquid, etc.).

Its core advantages are high conversion efficiency (electrical energy to thermal energy is more than 90%), fast response (heating as soon as power is turned on, no delay) and strong adaptability (through material and structural design, it can adapt to different temperature requirements, such as low-temperature drying below 100°C and high-temperature furnaces above 1000°C).

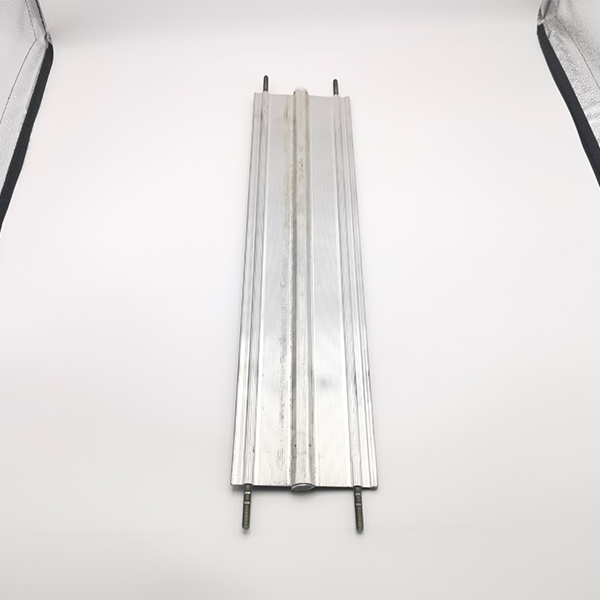

The electric heater heating element adopts high-purity nickel-chromium alloy heating wire and ceramic insulation skeleton,

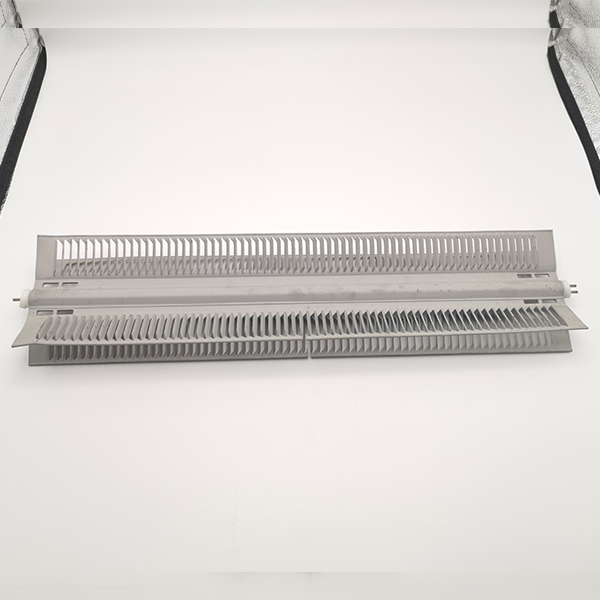

The finned heating element is designed for high-efficiency radiators, automotive heating systems and industrial hot air equipment.

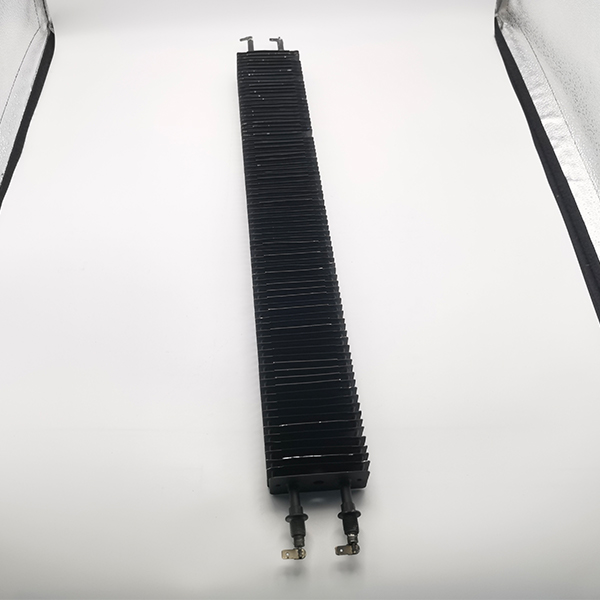

Fin-type heating elements designed for home heaters, commercial industrial HVAC systems and cold chain equipment

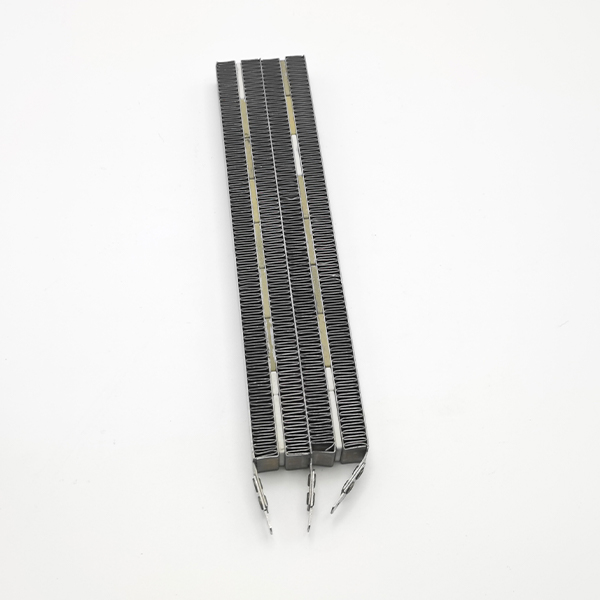

Semiconductor ceramic heating elements designed for home appliances, industrial equipment and new energy vehicles, using rare earth doped barium titanate

Electric fireplace heating element

The electric fireplace heating element is the core component of the electric fireplace to achieve the dual functions of “heat-visual”. It must not only efficiently generate heat to simulate the heating effect of a traditional fireplace, but also cooperate with optical design (such as flame lamps and reflective structures) to create a realistic flame visual experience. Its design must take into account thermal efficiency, safety, and aesthetics. Compared with ordinary electric heater elements, it emphasizes the integration with the “simulation scene”.

Electric fireplace heating elements are mostly made into sheets, honeycombs or tubes, with an insulating layer (such as aluminum oxide) on the surface, and are often integrated into aluminum heat sinks or embedded in simulated firewood textures. PTC is responsible for stable heating, and LED lights simulate flame jumping through dynamic light and shadow (with a microprocessor to control the flashing frequency), achieving a “heat-visual” separation but synergistic effect.

Home appliances: industrial heaters, air conditioning auxiliary heating modules, electric heaters, constant temperature water heaters.

Specially designed for home appliances, industrial equipment and new energy vehicles, the semiconductor ceramic heating element adopts rare earth doped barium titanate

The tubular heating element is designed for industrial hot air systems, agricultural greenhouse heating and household heaters. It adopts stainless steel 316L + ceramic fiber insulation structure

commercial display equipment and smart homes adopts nano-ceramic infrared radiation coating + aviation-grade aluminum alloy heat dissipation structure

Air conditioner heating element

The heating element of an air conditioner is the core component of its heating function. It is mainly used to supplement or replace heat pump heating to ensure that heat can be efficiently delivered to the room in low temperature environments (such as winter). Unlike the cooling mode (heat transfer through refrigerant circulation), the essence of the heating element is to directly convert electrical energy into thermal energy (electrical heat conversion) or to assist in improving the heating efficiency of the heat pump.

Air conditioning heating elements are key components for “emergency heating” and “comfort protection”, among which PTC ceramics have become the mainstream due to their safety and reliability. In the future, air conditioning heating elements will pay more attention to high efficiency and energy saving (such as intelligent power regulation) and user experience (such as low noise and uniform heating), and adapt to different climate and scene requirements.

The heating element is specially designed for split air conditioners, central air conditioners and industrial heat pump systems.

Verbrauchsgeräte: Zentrale Klimaanlagen, Zusatzheizungen, Wärmepumpensysteme für Wohngebäude, intelligente Lüftungsgeräte für Wohngebäude.

The finned tube heating element is designed for industrial duct systems, agricultural greenhouse heating and commercial heaters.

A high-performance heating element designed for industrial heat treatment furnaces, semiconductor annealing equipment

Siehe ein individuelles Angebot

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 40 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.