Summary: Understanding the classification of heating elements is essential for choosing the right solution in various industries. This guide mainly introduces the classification of heating elements from five aspects: materials, design, shape, application, and technology comparison. The article provides technical parameters of more than 10 heating element product applications and shares the best practices for heating element installation. You can also learn the difference between hot tub heating elements and electric water heater heating elements, and explore material selection criteria.

1. Material-Based Classification

Heating elements are fundamentally categorized by their resistive materials:

a) Metal Alloy Elements

- Nichrome (NiCr 80/20):

- Resistivity: 1.08 Ω·mm²/m (20°C)

- Max Temp: 1250°C (air)

- Applications: Residential water heaters, hair dryers

- Cost: $0.5-1.2/kg

- Kanthal (FeCrAl):

- Resistivity: 1.45 Ω·mm²/m

- Oxidation limit: 1300°C in air

- Applications: Industrial furnaces, kilns

- Thermal cycling resistance: 10,000+ cycles

b) Ceramic Heating Elements

Ceramic heating elements use doped aluminum oxide (Al₂O₃) substrates:

- Operating temp: 1500°C (continuous)

- Thermal shock resistance: ΔT=800°C (quench test)

- Dielectric strength: 20kV/mm

- Applications: Semiconductor dryers, aerospace ignition systems

c) Silicon Carbide (SiC) Elements

- Resistivity: 0.075 Ω·mm²/m (non-linear)

- Max temp: 1600°C (inert gas)

- Features: Fast thermal response (≤5°C/s)

- Applications: Glass melting furnaces, induction heating systems

2. Design-Based Classification

a) Coiled Elements

- Wire diameter: 0.5-1.5mm (NiCr)

- Surface load: 1.5-2.5W/cm² (water heating)

- Efficiency: 92-98% (quartz sleeves included)

- Common in: Electric kettles, coffee makers

b) Cartridge Elements

- Length: 150-600mm (customizable)

- Seal rating: IP68 (1m submersion)

- Power density: 8-15W/cm²

- Applications: Electric water heater elements, steam generators

c) Radiant Elements

- Thickness: 1-3mm (flat ribbon)

- Emissivity: 0.92 (infrared range)

- Mounting: Flange/water-cooled base

- Used in: Hot tub heating elements, industrial ovens

3. Shape-Based Classification of Heating Elements

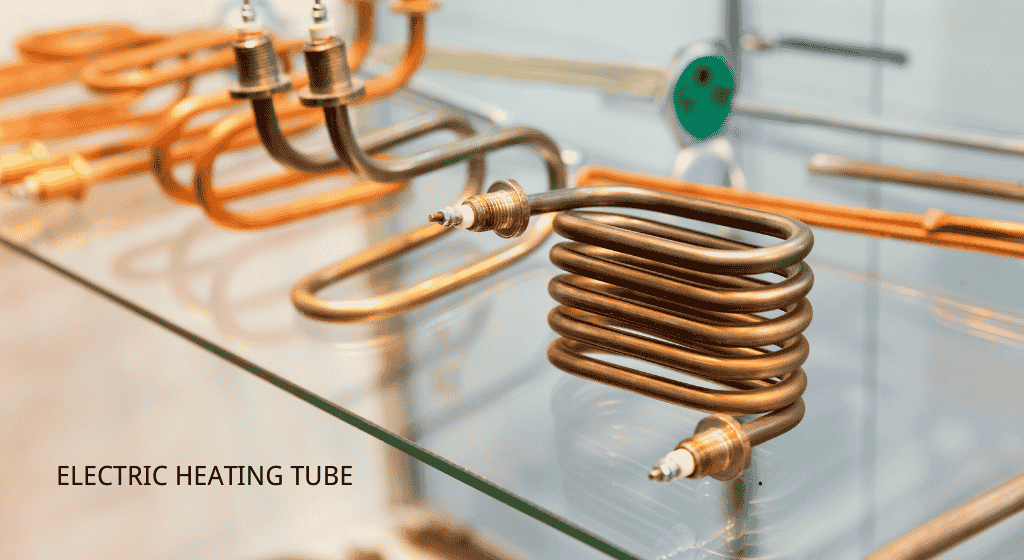

a) Tubular Heating Elements

- Structure: Cylindrical design with coiled resistance wire (NiCr 80/20) inside a stainless steel sheath.

- Parameters:

- Power density: 8-15W/cm²

- Max temp: 800°C (oil immersion)

- Material: SUS316L (saltwater resistant)

- Applications:

- Electric water heaters (5-10kW units)

- Industrial boilers (steam generation)

- Food processing (pasteurization tunnels)

b) Disc-Shaped Heating Elements

- Structure: Flat spiral wound into a disc (Kanthal A1 alloy).

- Parameters:

- Thickness: 3-5mm

- Diameter: 50-200mm

- Surface load: 10-15W/cm²

- Applications:

- Electric rice cookers (300-800W)

- Hair straighteners (ceramic-coated discs)

- Thermal printers (flatbed models)

c) Thin-Film Heating Elements

- Structure: 0.1-0.3mm thick PTC ceramic layer on aluminum substrate.

- Parameters:

- Heating speed: ≤5°C/s

- Max temp: 250°C (continuous)

- Power density: 5-8W/cm²

- Applications:

- Electric blankets (3D knitted fabric integration)

- Automotive dashboards (defrost systems)

- 3D printer hotends (PLA filament heating)

d) Spiral Heating Elements

- Structure: Helical coil (NiCr 60/15) with ceramic insulation.

- Parameters:

- Wire diameter: 0.8-1.2mm

- Resistance: 10-50Ω (per meter)

- Max temp: 1200°C (vacuum environments)

- Applications:

- Toaster ovens (broil settings)

- Laboratory muffle furnaces

- Gas grill igniters

e) Band-Type Heating Elements

- Structure: Flat ribbon coiled into a spiral band.

- Parameters:

- Width: 10-50mm

- Thickness: 0.5-2mm

- Operating temp: 600°C (air)

- Applications:

- Conveyor belt ovens (bakery equipment)

- Plastic extruders (drying systems)

- Textile curing machines

f) Cartridge Heating Elements

- Structure: Cylindrical sealed unit with threaded ends.

- Parameters:

- Length: 50-300mm

- Power: 1-5kW

- IP Rating: IP68 (submersible)

- Applications:

- Electric kettles (auto-shutoff models)

- Steam irons (1.5m braided hose)

- Hydronic heating systems

g) Foil Heating Elements

- Structure: Vapor-deposited Nichrome on polymer film.

- Parameters:

- Thickness: 0.05-0.2mm

- Flexibility: 180° bend radius

- Power density: 3-5W/cm²

- Applications:

- Medical warmers (IV fluid heating)

- Aerospace de-icing systems

- Wearable heated clothing

h) Rod-Type Heating Elements

- Structure: Straight wire (Kanthal AF) with ceramic insulation.

- Parameters:

- Diameter: 3-8mm

- Max temp: 1400°C (inert gas)

- Tolerance: ±0.05mm

- Applications:

- Electric arc furnaces (steel melting)

- Ceramic kilns (kiln furniture)

- Semiconductor epitaxy reactors

i) Honeycomb Heating Elements

- Structure: Porous alumina tubes with radial fins.

- Parameters:

- Surface area: 200-300cm²/g

- Thermal shock resistance: ΔT=500°C

- Max pressure: 10bar (water side)

- Applications:

- Household humidifiers

- Aquarium heaters (submersible)

- Hydroponic systems

4. Application-Specific Categories

a) Water Heater Heating Elements

- Material: SUS316L stainless steel (chloride resistance)

- Surface load: ≤1.5W/cm² (prevents scaling)

- Standards: IEC 60335-2-15 (max 3kW/L)

- Efficiency: 96% (with magnesium anode)

b) Ceramic Heating Elements

- Thermal mass: 0.8-1.2J/g°C

- Response time: <10s (vs. 30s for metal coils)

- Key feature: No oxidation at 1000°C

- Applications: Dental curing lights, laser diodes

c) Hot Tub Heating Elements

- Saltwater compatibility: ASTM B117 salt spray test

- Safety features: Automatic thermal cutoff (104°F)

- Flow rate requirement: ≥15L/min

- Energy consumption: 4.5kW @ 75°F rise

d) Electric Shower Heating Elements

- Element Type: Tubular (SUS316L)

- Power: 8.5kW @ 230V

- Safety: IPX4 waterproof rating

e) Air Fryers Heating Elements

- Element Type: Band-type (Kanthal A1)

- Temp Range: 80-200°C

- Feature: Rapid air circulation

f) Electric Chainsaw Heating Elements

- Element Type: Rod-type (NiCr 60/15)

- Power: 2kW cold start

- Application: Chain brake heating

g) Hot Air Balloon Heating Elements

- Element Type: Honeycomb (ceramic)

- Fuel: Propane burner integration

- Temp: 1200°C flameless combustion

h) Electric Guitar Pickup Heating Elements

- Element Type: Thin-film (PTC)

- Function: Piezoelectric signal amplification

- Size: 10mm×2mm

i) Solar Water Heater Heating Elements

- Element Type: U-tube (copper alloy)

- Working Fluid: Propylene glycol

- Efficiency: 82% thermal conversion

j) Electric Snow Melting Mat Heating Elements

- Element Type: Foil (Nichrome)

- Area: 1.2m×0.6m

- Power: 220W/m²

k) 3D Printer Bed Heating Elements

- Element Type: Flexible foil

- Material: Kapton-coated polyimide

- Temp Stability: ±1°C (PID control)

l) Electric Scooter Throttle Heating Elements

- Element Type: Ribbon (Kanthal AF)

- Resistance: 5Ω±5%

- Response: 0.5s full heat-up

m) Medical Incubator Heating Elements

- Element Type: Cartridge (IP68)

- Material: Titanium-coated NiCr

- Safety: Dual thermal fuses

5. Technical Comparison Table

| Parameter | Nichrome 80/20 | Kanthal A1 | Silicon Carbide | Ceramic (Al₂O₃) |

|---|---|---|---|---|

| Max Temp (°C) | 1250 | 1400 | 1600 | 1500 |

| Thermal Expansion | 1.7×10⁻⁶/°C | 1.3×10⁻⁶/°C | 4.5×10⁻⁶/°C | 8.0×10⁻⁶/°C |

| Thermal Conductivity | 11 W/m·K | 16 W/m·K | 35 W/m·K | 30 W/m·K |

| Cost ($/kg) | 1.2 | 0.8 | 15 | 50 |

Frequently Asked Questions (FAQ)

What’s the difference between ceramic heating elements and metal alloy types?

ANSWER: Ceramic elements operate at 1500°C (vs. 1250°C for Nichrome) with zero oxidation, but have lower thermal conductivity (30 vs. 16 W/m·K).

How to choose between water heater heating elements and cartridge types?

ANSWER: Use coiled elements for <5kW applications (max 3kW/L density). Cartridges suit high-flow systems (>15L/min) requiring IP68 sealing.

Can hot tub heating elements be used in saltwater pools?

ANSWER: Only if certified to ASTM B117 (500h salt spray test). Standard elements degrade in Cl⁻ concentrations >300ppm.

What causes electric heating element failure in high-humidity environments?

ANSWER: Electrolytic corrosion (Fe→Fe²⁺ + 2e⁻) when moisture penetrates seals. Use hermetic terminals (IP69K rated) for prevention.

About Zhongshan Jinzhong Electric Heat Technology Co., Ltd.

As a global leader in heating element manufacturing, we supply components to Philips, Midea, Delonghi, and SEB Group. Our expertise includes:

- Custom Kanthal/Nichrome alloy extrusion (±0.05mm tolerance)

- Laser-welded ceramic-to-metal seals (leak rate <1×10⁻⁸ Pa·m³/s)

- A2LA-accredited testing (IECEx, UL, CE certifications)

Core Competencies:

- High-temperature ceramic elements (1600°C continuous)

- Saltwater-resistant hot tub heating elements (5-year lifespan)

- Custom electric water heater elements with IoT integration

Contact our engineering team for OEM solutions with MOQ as low as 1000pcs. All products comply with RoHS 3 and REACH SVHC directives.