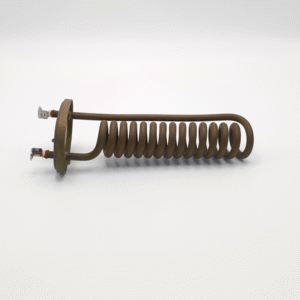

The die-casting heating element adopts ceramic substrate and thick film resistor slurry printing process, integrated PID temperature control module, achieves 3-5 seconds fast heating, energy efficiency ≥96%, working temperature range 80℃-450℃, supports power (1000W-5000W) and shape customization, has IPX6 waterproof, anti-aluminum corrosion and dry burning resistance, adapts to high-frequency continuous die-casting scenes, and has a lifespan of more than 50,000 hours, meeting the needs of high-precision and high-stability die-casting processes.

Minimum order quantity: 1000

Delivery time: 15-25 days

Factory location: Zhongshan, Guangdong, China

Industrial die-casting machines (aluminum/magnesium alloys), automotive parts die-casting equipment, home appliance accessories die-casting molds, medical equipment die-casting molding machines, new energy battery housing die-casting lines, aerospace parts die-casting systems, LED lamp holder die-casting equipment, industrial mold constant temperature heating systems.

| Parameter | Specification Range |

|---|---|

| Power Range | 10kW-2000kW |

| Operating Voltage | 380V (three-phase, standard); 220V/480V (optional, for regional voltage compatibility) |

| Resistance Value | 5Ω-50Ω (single unit or multi-unit combination) |

| Operating Temperature | Surface: 200℃-600℃ (normal); Max. withstand: 700℃ (short-term overload protection) |

| Material | Heating element: Nickel-chromium alloy (Cr20Ni80, Φ0.8mm-Φ2.5mm); Housing: Aluminum alloy (6063/6061) or 316 stainless steel |

| Dimensions | Length: 1000mm-5000mm; Diameter: 100mm-300mm (customizable per die casting machine model) |

| Service Life | 8000h-12000h (normal use, no overloading/corrosion) |

High-Efficiency Heating: Nickelchromium alloy guarantees quick heat transfer, hence lowering warm-up time by 20%–30% versus conventional heating components.

Surface temp up to 600°C (with optional high-temperature insulation) adapts to aluminum/zn alloy die casting; usual mold temps: 180400°C.

Compatible with worldwide industrial power systems, voltage flexibility: 380V standard plus optional 220V/480V.

Length, diameter, and power adaptable to meet typical die casting machines (e.g., Yizumi, LK, Buhler).

Durable construction: Either 316 stainless steel (corrosion-resistant for hostile conditions) or lightweight, thermally conductive aluminum alloy housing

Long Service Life: Optimized heat dissipation lessens element fatigue; 8000h+ lifespan under ordinary use.

Built-in overheat protection (autoshutoff at 700°C) protects from damage from unusual circumstances, so guaranteeing safe operation.

Thermal efficiency ≥88% lowers energy use during continuous casting processes.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.