Specially designed for preparing ultrapure water in distilled water machines, it uses high-precision heating technology to evaporate and condense raw water, remove impurities and ions, and produce distilled water with a resistivity of ≥18 MΩ·cm, meeting the high-purity water needs in laboratories, medical treatment, pharmaceuticals and other fields.

MOQ:1000PCS

Lead time:25days

Factory location: Zhongshan, Guangdong, China

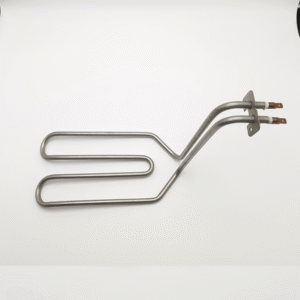

Engineered for distilled water generation systems, high-performance electric heating components are intended to effectively convert water into purifying steam and condense it into high-purity distilled water. These optimized for durability, corrosion resistance, and energy efficiency components are essential for medical, laboratory, and industrial uses demanding ultra-pure water.

Operating at temperatures up to 1200°C, high resistivity and oxidation resistance nickel-chromium (NiCr) or iron-chromium-aluminum (FeCrAl) alloy.

Insulation: magnesium oxide (MgO) powder coating to guarantee thermal stability and prevent current leakage.

Stainless steel 304/316L enclosed with ceramic seals to resist corrosion and contamination .

Power Range: 500W–1500W (adjustable via thermostat) to match varying distillation demands .

Thermal Efficiency: ≥95% energy conversion rate, minimizing heat loss and operational costs .

Steam Generation: Rapid boiling of water (3–5L/hour) with minimal energy consumption .

Overheat Protection: Automatic shutdown at 120°C (adjustable) to prevent dry boiling or component damage .

Anti-Dry Burn: Built-in sensors detect low water levels and cut power to avoid overheating .

IPX4 Waterproof: Protection against splashing and humidity for safe operation in humid environments .

Voltage Compatibility: AC 110V–240V/DC 12V–48V for global use .

Mounting Designs: Vertical or horizontal configurations with flange or threaded interfaces .

Coating Options: Nano-ceramic or PTFE anti-scaling coatings to reduce maintenance frequency .

Produces 0 ppm distilled water for autoclaves, IV solutions, and sensitive experiments .

Eliminates 99.9% of contaminants (e.g., bacteria, heavy metals) via steam distillation .

Critical for battery manufacturing, pharmaceuticals, and electronics cleaning .

Compatible with high-purity water loops requiring continuous distillation.

Compact units for kitchens or clinics, combining energy efficiency with safety features .

Reduced Scaling: Anti-scaling coatings decrease limescale buildup by 60%, lowering maintenance needs .

Uniform Heating: Vertical steam pathways ensure consistent temperature distribution, minimizing hotspots .

Energy Savings: Optimized power consumption reduces operational costs by 20% vs. traditional elements .

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.