You can test water heater elements by turning off the power, accessing the element, and using a multimeter to check for proper resistance.

⚠️ Always turn off power at the breaker and confirm with a voltage tester before you touch any wires.

Routine testing helps your water heater run efficiently and prevents unnecessary replacements.

- Sediment buildup and corrosion force your heater to work harder, raising energy bills.

- Regular test water heater efforts catch minor issues before they lead to costly failures.

| Environmental Factor | Impact on Water Heater Element Failure |

|---|---|

| Hard Water | Increases sediment, corrosion, and element failure |

| Outdoor/Moist Installation | Accelerates corrosion and reduces lifespan |

Essential Safety Steps Before You Test Water Heater Elements

Testing a water heater element requires strict attention to safety. Electricity and water create a hazardous environment. You must follow each step carefully to protect yourself and your home.

Power Off and Verification

Locating and Switching Off the Circuit Breaker

Before you touch any part of your electric water heater, you need to disconnect it from the electrical supply. Locate your home’s electrical panel. Find the breaker labeled for your water heater and switch it to the “off” position. This step prevents accidental electric shock.

Using a Voltage Tester for Safety

Turning off the breaker is not enough. You must confirm that the water heater is completely de-energized. Follow these steps to verify power is off:

- Turn off the power at the circuit breaker.

- Remove the metal cover plates to access the thermostats and heating elements.

- Use a non-contact voltage tester to check for voltage at all electrical connections.

- If wires are inside a metal conduit, remove the thermostat cover and insulation to reach wires near the high-temperature cutoff switch.

- Hold the tester against the metal shell of the water heater for an extra safety check.

- Only proceed if the tester shows no voltage anywhere.

⚠️ Never skip voltage testing. Even a small mistake can cause serious injury.

Personal Protective Measures

Recommended Safety Gear

You should always wear the right personal protective equipment (PPE) when working on an electric water heater. Insulated gloves protect your hands from electric shock. Safety glasses shield your eyes from sparks or debris. Arc-rated clothing adds another layer of protection.

Creating a Safe Work Area

A clean, dry workspace reduces risk. Remove any water from the floor around the water heater. Keep your tools organized and within reach. Make sure the area is well-lit so you can see all connections clearly.

Handling Electrical and Water Components

Preventing Electric Shock

Electric water heater repairs come with several hazards. The most common risks and their solutions include:

| Electrical Hazard | Description | Mitigation Strategies |

|---|---|---|

| Wet or Damp Environments | Water conducts electricity, increasing risk of shock especially with damaged insulation. | Keep work areas dry; ensure hands are dry before handling; do not operate wet equipment; consult electricians if equipment is wet. |

| Faulty or Damaged Equipment | Cracks, cuts, frayed wires, or damaged insulation can cause shocks or electrocution. | Inspect tools and equipment before use; remove damaged items from service; do not use electrical tape as repair; follow Lockout/Tagout (LOTO) procedures during maintenance. |

| Lack of Proper Grounding | Improper grounding leads to electrical shock; accounts for ~30% of electrical fatalities. | Ensure all equipment is properly grounded or double-insulated; inspect grounding prongs; use double-insulated tools. |

| Working in Wet Conditions | Moisture can energize equipment surfaces, increasing shock risk. | Use Ground Fault Circuit Interrupters (GFCIs) in wet areas; dry hands before handling; only use equipment designed for wet conditions. |

| General Safety Practices | Accidental energizing of equipment during maintenance can cause injury. | De-energize equipment and apply Lockout/Tagout procedures; wear non-conductive PPE; only trained personnel handle live wires; conduct regular inspections. |

Avoiding Water Damage

Water leaks can damage your electric water heater and create slip hazards. Always check for leaks before you begin. Place towels or a shallow pan under the unit to catch any drips. If you must drain the tank, follow the manufacturer’s instructions to prevent flooding.

Tip: Keep a fire extinguisher and first aid kit nearby when working on any electrical appliance.

Tools and Materials to Test Water Heater Elements

Selecting the right tools and materials ensures you can test water heater elements safely and accurately. You need to prepare before you begin any diagnostic or repair work.

Choosing the Right Multimeter

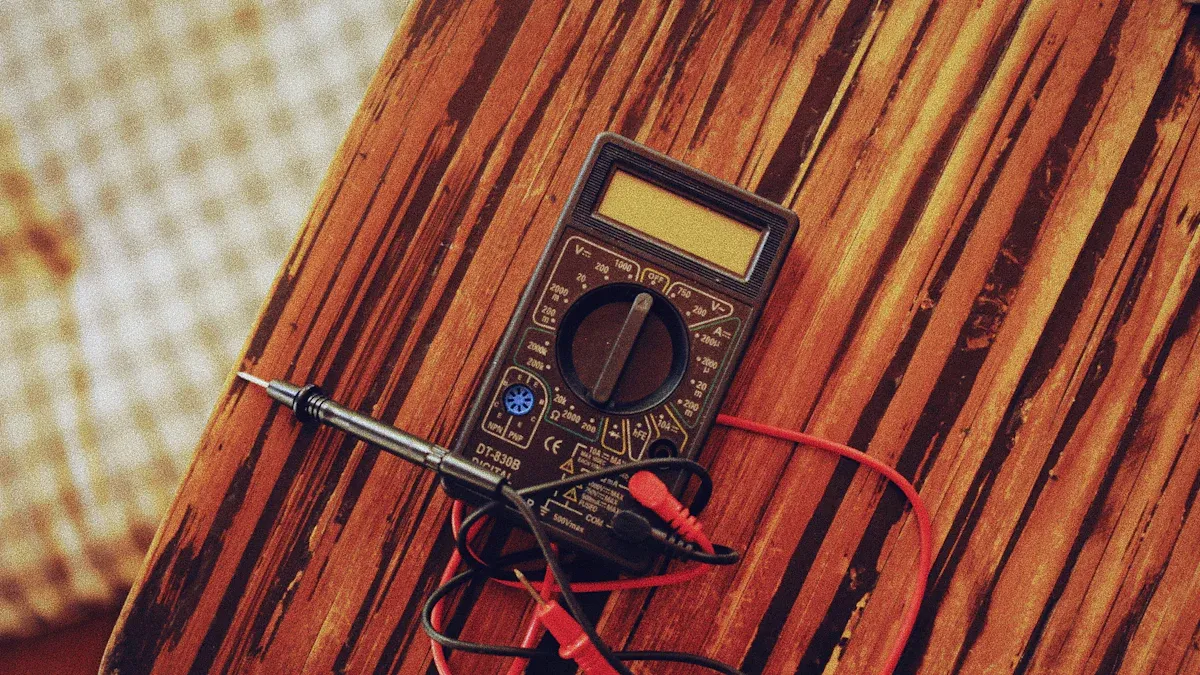

Selecting a Multimeter for Resistance Testing

You should use a digital multimeter for testing water heater elements. Digital models provide precise readings and are easier to interpret than analog types. When choosing a multimeter, prioritize these features:

- Auto-ranging capability for simple operation and accurate results.

- Safety ratings of CAT III or higher to protect against voltage spikes.

- Essential functions such as resistance (ohms) and continuity testing.

Clamp meters focus on current measurement and do not suit resistance testing for heating elements. Always set your digital multimeter to the lowest ohms setting for accurate continuity and resistance checks.

Setting Up the Multimeter

Before testing, turn off the power and verify no voltage is present. Remove the access panels to reach the element. Disconnect the wires from the element to isolate it. Set your multimeter to the lowest resistance range. Place the leads on the element terminals to check for continuity and resistance. A reading of zero ohms indicates proper continuity. If you see no continuity or abnormal resistance, you should replace the element.

Essential Hand Tools

Screwdrivers and Wrenches

You need a screwdriver, either flathead or Phillips, to remove access panels and disconnect wires. A heating element wrench fits the element perfectly and allows you to loosen or tighten it without causing damage. Pipe wrenches help with fittings, and a drain valve wrench assists in removing or tightening the drain valve.

Optional Tools for Easier Access

Some situations require extra tools for convenience and safety:

- Teflon tape for sealing threaded connections and preventing leaks.

- Protective gloves and eyewear to shield your hands and eyes from burns, cuts, or debris.

- A shallow pan or towels to catch water drips during maintenance.

Tip: Keep your tools organized and within reach to streamline the process and reduce the risk of accidents.

Replacement Parts and Accessories

Identifying Compatible Heating Elements

When you need to replace heating elements, always match the resistance values and follow the manufacturer’s specifications. Most water heaters use two elements per tank—an upper and a lower. Signs that you need a new element include inconsistent water temperature, reduced hot water, or strange noises. Inspect the terminals for corrosion or damage before replacing.

You can ensure compatibility by using manufacturer lookup tools or retailer compatibility checkers. Enter your model or part number to find the correct heating elements. Purchase only from authorized retailers or official manufacturer websites to guarantee authenticity.

Gaskets and Sealants

Gaskets prevent leaks when you install new heating elements. Always use a new gasket with each replacement. Teflon tape or approved sealants help create a watertight seal on threaded connections. Check the packaging for official branding and part numbers to confirm authenticity.

Note: Review warranty and return policies before purchasing replacement parts. Contact customer support if you have concerns about authenticity.

Preparing to Test Water Heater Elements

Before you begin testing, you must prepare your water heater and workspace. Careful preparation ensures your safety and helps you avoid damage to the unit or its heating elements.

Shutting Down the Water Heater

Turning Off Power and Allowing to Cool

Start by disconnecting the power supply to your water heater. Locate the circuit breaker and switch it off. Confirm the power is off with a multimeter or voltage tester. This step prevents electrical shock and aligns with manufacturer safety guidelines. For electric models, unplug the unit if possible. Next, run hot water from a nearby faucet for 10 to 30 minutes. This process cools the tank and reduces the risk of burns. Always wear heavy gloves to protect your hands from residual heat.

⚠️ Never skip the cooling step. Hot water inside the tank can cause severe burns.

Draining the Tank (If Needed)

When and How to Drain Safely

You may need to drain the tank if the heating elements sit below the water line. Shut off the cold water supply valve to the water heater. Attach a garden hose to the drain valve at the base of the tank. Direct the hose to a safe drainage area or a large bucket. Open the drain valve and allow water to flow until the level drops below the heating elements. This step prevents water from spilling when you remove the elements. Always close the drain valve once you finish.

Tip: Open a hot water faucet in your home while draining. This action helps air enter the tank and speeds up the draining process.

Accessing the Heating Element

Removing Access Panels

Locate the access panels on the side of your water heater. Use a screwdriver to remove the screws and lift away the panel. Fold back any insulation to expose the heating elements and wiring. Keep all screws and panels in a safe place for reassembly.

Identifying and Disconnecting Element Wires

Before touching any wires, verify again that no power reaches the unit using your multimeter. Identify the wires connected to the heating elements. Take a photo or make a note of their positions for easy reinstallation. Loosen the terminal screws and gently disconnect the wires. Handle all electrical components with care to avoid damaging the connections.

Note: If you feel unsure about handling electrical wiring, consider consulting a licensed professional.

By following these steps, you create a safe environment for testing and ensure your water heater remains in good condition.

Step-by-Step Guide to Test Water Heater Elements

Testing your water heater elements requires careful setup and attention to detail. By following these steps, you ensure accurate results and protect yourself from hazards.

Setting Up the Multimeter

Selecting the Correct Ohms Setting

You must set your multimeter to the correct ohms (Ω) setting before you begin. This setting allows you to measure the resistance of the heating elements accurately. Most digital multimeters have an auto-ranging feature, but if yours does not, select the lowest resistance range available. This step ensures you can detect even small changes in resistance.

Testing the Multimeter Function

Before you test water heater elements, check that your multimeter works properly. Touch the two probes together. The display should show a reading close to zero, confirming the device is ready. If you see no change or an error, replace the batteries or consult the manual. Always verify your tool before you proceed.

Tip: Never attempt to test heating elements with the power on. This mistake can damage your multimeter and put you at risk of electric shock.

Measuring Resistance and Continuity

Placing Probes on Element Terminals

To test water heater elements, follow these steps:

- Turn off the power at the circuit breaker and confirm with a voltage tester.

- Remove the access panel and insulation to expose the heating elements.

- Disconnect both wires from the element terminals. Keep the wires separated from each other and any metal parts.

- Set your multimeter to the ohms setting.

- Place one probe on each terminal (screw) of the heating element.

This process isolates the element and ensures you get an accurate reading.

Reading and Recording Resistance Values

Once you place the probes, read the resistance value displayed on the multimeter. A functional element typically shows a resistance between 10 and 30 ohms, depending on the wattage and voltage. Record the value for both the upper and lower elements. If you see a reading of zero, the element is shorted. If the display shows infinite resistance or “OL,” the element is open or burned out.

Common mistakes include leaving the wires connected or testing only one element. Always disconnect the wires and test both elements to avoid missing a hidden problem.

Interpreting Test Results

Normal Resistance Ranges by Wattage

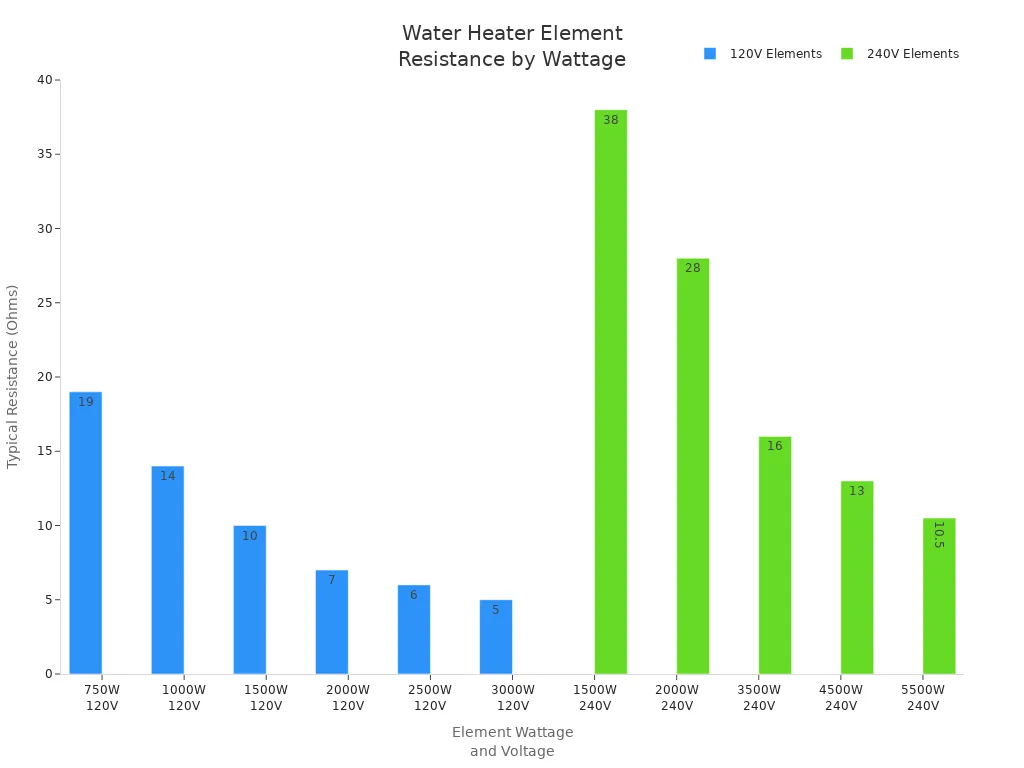

The resistance value you measure depends on the wattage and voltage of your water heater element. Use the table below to compare your readings:

| Wattage (W) | Voltage (V) | Typical Resistance (Ohms) |

|---|---|---|

| 750 | 120 | ~19 |

| 1000 | 120 | ~14 |

| 1500 | 120 | ~10 |

| 2000 | 120 | ~7 |

| 2500 | 120 | ~6 |

| 3000 | 120 | ~5 |

| 1500 | 240 | ~38 |

| 2000 | 240 | ~28 |

| 3500 | 240 | ~16 |

| 4500 | 240 | ~13 |

| 5500 | 240 | ~10.5 |

A resistance reading within these ranges means your element is likely in good condition. If your reading falls outside these values, you may need to replace the element.

Signs of a Faulty or Broken Element

You can identify a faulty element by these signs:

- A resistance reading below 5 ohms suggests a short circuit.

- A reading above 25-38 ohms (depending on wattage) or infinite resistance means the element is burned out.

- No continuity (no beep in continuity mode) indicates a broken circuit.

- If you detect resistance between the element terminal and the metal tank, the element is shorted to ground and must be replaced.

If you see visible corrosion or damage on the element, replacement is necessary. When in doubt, consult a professional to avoid further damage to your water heater.

By following these steps, you can confidently test water heater elements and ensure your system operates efficiently. Regular checks help you catch problems early and extend the life of your heating elements.

Troubleshooting When You Test Water Heater Elements

No Reading or Infinite Resistance

Common Causes and Solutions

When you test a water heater element and see no reading or infinite resistance on your multimeter, you face a classic sign of a failed element. Several issues can cause this result:

- A broken coil inside the element creates an open circuit, so electricity cannot flow.

- Corrosion or pinholes in the element’s sheath allow water to enter, which leads to failure.

- If you find a hole in the sheath, the element is defective and needs replacement.

- Sometimes, a tripped GFCI points to a short caused by water intrusion.

- Sediment or water left in the tank can cause strange readings, so always drain as needed.

To troubleshoot, always disconnect power and wires before testing. Set your multimeter to ohms and measure resistance between the element terminals. If you get infinite resistance or no continuity, the element is bad. If both elements test fine, check the thermostats, as a faulty thermostat can also disrupt the power supply. Test both the upper and lower elements to ensure your system works properly.

Tip: Replacement tools are affordable, and swapping out a failed element is a common repair.

Low or High Resistance Readings

What These Results Mean

If your multimeter shows a resistance reading outside the normal 10–30 ohm range, you likely have a problem. Low resistance readings often point to a short circuit inside the element. High resistance or infinite readings indicate an open circuit or a broken coil.

Follow these troubleshooting steps:

- Turn off power to the water heater.

- Disconnect wires from each heating element.

- Set your multimeter to the ohm setting.

- Measure resistance across the terminals.

- Compare your results to the 10–30 ohm standard.

- If readings fall outside this range, replace the element.

- Test both elements, since one failed element can cause insufficient hot water.

- If both elements test normal, check the thermostats next.

Deciding When to Replace the Element

Replace the element if you see:

- Infinite resistance (open circuit)

- Very low resistance (short circuit)

- Any reading outside the normal range

If the elements test normal but you still have issues, inspect the thermostats and look for other problems like sediment buildup, high water pressure, or corrosion. Always follow safety precautions and call a professional if you feel unsure.

Other Signs of Element Failure

Unusual Noises or Odors

You may notice strange sounds from your water heater tank. Popping noises often mean mineral deposits cause steam flashes. Humming can signal a loose element. Crackling may come from condensation, while sizzling points to water leaks. Screeching usually means a partially closed inlet valve. These noises help you spot trouble before it becomes severe.

Inconsistent or No Hot Water

Other signs of element failure include:

- Lukewarm water from faucets and showers

- Hot water running out quickly

- Longer heating times than usual

- Fluctuating or inconsistent water temperatures

Visual inspection can also reveal melted or burned areas, pinholes, rust, or heavy sediment buildup on the element. These symptoms, combined with resistance testing, give you a clear diagnosis.

Note: If you see multiple warning signs or feel uncertain, contact a licensed technician to prevent further damage to your electric water heater.

Reassembly and Restoring Power After You Test Water Heater

Reinstalling Access Panels and Components

After you finish testing or replacing the water heater element, you must reassemble the unit with care. Proper reassembly ensures safety, maintains efficiency, and prevents future hazards.

Securing All Parts and Checking for Leaks

Follow these steps to secure all parts and restore your water heater to its original condition:

- Confirm that the power remains off by using a non-contact circuit tester or volt meter. This step protects you from accidental electric shock.

- Replace the junction box cover. Secure it tightly to minimize fire and electric shock risks.

- Reinstall the upper heating element cover. Make sure it fits snugly over the element and wiring.

- Return the insulation to its original position. Tuck it back under the water heater’s jacket to maintain energy efficiency and prevent heat loss.

- Replace any plastic protectors or additional covers you removed during testing.

🛠️ Tip: Double-check that all screws and fasteners are tight. Loose panels can cause rattling noises and reduce the effectiveness of the insulation.

Once you finish reassembly, inspect the area around the heating element for any signs of leaks. If you see moisture, tighten the element or fittings as needed. A dry workspace signals that you have sealed everything correctly.

Restoring Power Safely

Restoring power to your water heater requires careful attention to detail. You must ensure the tank is full and free of air before energizing the element.

Turning the Breaker Back On

Before you restore power, open the nearest hot water tap and let it run until you see a steady stream of water without air bubbles. This step purges air from the system and prevents the new heating element from running dry, which can cause it to burn out in seconds. Once you confirm the tank is full and all air is out, return to your electrical panel and switch the breaker back on.

⚡ Alert: Never turn on the power if the tank is empty or partially filled. Dry firing the element will cause immediate damage.

Monitoring Initial Operation

After you restore power, monitor the water heater’s operation closely. Listen for unusual noises and check for leaks around the element and access panels. Feel the hot water tap to confirm the water heats up as expected. If you notice any issues, turn off the power immediately and inspect your work.

You should also check the area for any lingering moisture or signs of overheating. A properly reassembled and powered water heater will operate quietly and efficiently, delivering reliable hot water to your home.

✅ Note: Regular monitoring after reassembly helps you catch small problems before they become major repairs.

When to Call a Professional for Water Heater Testing

Complex Electrical or Plumbing Issues

Water heater testing sometimes reveals problems that go beyond basic troubleshooting. You may encounter situations where your safety or the integrity of your home is at risk. In these cases, you should always contact a licensed professional.

Signs You Need Expert Help

You can handle many routine maintenance tasks, but some issues require specialized skills and equipment. Watch for these warning signs:

- Tank leaks often signal the need for a complete water heater replacement. Only a professional can install a new unit safely and in compliance with local codes.

- Gas-related problems, such as the smell of gas or a malfunctioning pilot light, demand immediate attention from a licensed technician. Attempting to fix gas issues yourself puts you and your household at serious risk.

- Electrical faults in electric water heaters, including tripped breakers, burnt wires, or persistent power loss, should prompt you to call an electrician. If you feel uncertain about any electrical component, do not proceed alone.

- Persistent or unresolved problems after you complete basic troubleshooting indicate deeper issues. Complex failures may involve thermostats, wiring, or plumbing connections that only an expert can diagnose and repair.

⚠️ Alert: Never ignore unusual smells, visible damage, or repeated system failures. Professional intervention protects your safety and prevents further property damage.

Warranty and Insurance Considerations

You want to protect your investment in your water heater. Understanding how warranties and insurance policies address DIY repairs helps you avoid costly mistakes.

Protecting Your Investment

Most home warranties and insurance policies set clear guidelines for water heater maintenance and repairs. Consider these important points:

- Home warranties usually cover repairs and replacements due to normal wear and tear. However, they often exclude problems caused by neglect, improper maintenance, or incorrect installation.

- Warranty coverage typically requires that all repairs and maintenance be performed by licensed professionals. If you attempt DIY repairs, you risk voiding your warranty and losing coverage for future claims.

- DIY testing and repairs are not recommended or covered by most warranty providers. Professional service ensures you meet all policy requirements.

- You may need to provide proof of regular maintenance, such as annual tank flushes, to keep your warranty valid.

- Insurance policies generally do not cover water heater repairs or replacements, viewing them as standard maintenance. They may cover damage from leaks only if caused by a covered peril, such as fire or natural disaster.

- Claims can be denied if the insurer finds evidence of excessive wear, lack of maintenance, or improper installation. DIY work rarely meets the standards required for coverage.

📝 Tip: Always keep records of professional maintenance and repairs. These documents help you support warranty or insurance claims and demonstrate responsible ownership.

By recognizing when to call a professional, you protect your home, your safety, and your financial investment.

Maintenance Tips After You Test Water Heater Elements

Regular Inspection and Testing Schedule

How Often to Test and What to Look For

You should inspect and test your water heater elements regularly to maintain peak performance and extend the lifespan of your unit. Experts recommend a minimum of one inspection per year for most electric tank-style water heaters. However, if your home uses a lot of hot water or you live in an area with hard water, you may need to check your system every three to six months.

- Biannual inspections help you catch early signs of wear, corrosion, or sediment buildup.

- Annual thermostat calibration ensures your heater maintains the correct temperature.

- Quarterly checks may be necessary for high-usage households or those with hard water.

During each inspection, look for:

- Signs of corrosion on the heating elements and tank

- Evidence of leaks around valves and connections

- Sediment buildup at the bottom of the tank

- Unusual noises or odors during operation

- Fluctuations in water temperature or reduced hot water supply

🛠️ Tip: Schedule a professional inspection once a year. A licensed technician can check heating elements, thermostats, anode rods, and pressure relief valves to ensure your system operates safely and efficiently.

Preventing Future Problems

Flushing the Tank

Sediment buildup is a leading cause of water heater element failure. You can prevent this by flushing your tank at least once a year. Flushing removes minerals and debris that settle at the bottom, which improves heat transfer and reduces energy consumption.

Steps to flush your tank:

- Turn off the power or gas supply and allow the water to cool.

- Shut off the cold water supply valve.

- Attach a garden hose to the drain valve and direct it to a safe drainage area.

- Open the drain valve and let the water flow until it runs clear.

- Close the valve, remove the hose, and restore the water supply.

💡 Note: Flushing your tank regularly helps prevent overheating, extends the life of your heating elements, and keeps your water heater running efficiently.

Addressing Hard Water Issues

Hard water accelerates sediment buildup and corrosion, which can shorten the lifespan of your water heater elements. If you notice frequent scaling or reduced efficiency, consider these steps:

- Install a water softener to reduce mineral content.

- Inspect and replace the anode rod annually to protect against internal corrosion.

- Increase inspection frequency to quarterly if your area has very hard water.

- Set your thermostat to around 120°F to minimize scaling and energy use.

You should also insulate your water heater tank and pipes to reduce heat loss and improve efficiency. Promptly fix any leaks you find during inspections to prevent water damage and maintain system integrity.

✅ Tip: Consistent maintenance and attention to water quality will help you avoid costly repairs and ensure reliable hot water for years to come.

Testing your water heater elements safely and efficiently requires a clear process:

- Turn off the power to prevent electrical hazards.

- Use a multimeter set to ohms to check element continuity.

- Replace elements only with those matching the correct voltage and wattage.

You protect your home and maintain efficiency by following these steps. Regular maintenance—such as flushing sediment, inspecting anode rods, and testing safety valves—prevents breakdowns and extends your system’s lifespan. If you ever feel unsure or face complex issues, always consult a licensed professional.

FAQ

How often should you test water heater elements?

You should test your water heater elements at least once a year. If you notice inconsistent hot water or live in a hard water area, increase the frequency to every six months.

Can you test a water heater element without removing it?

Yes, you can test the element without removing it. Disconnect the wires from the terminals, then use a multimeter to check resistance directly on the installed element.

What resistance reading means you need to replace the element?

A reading of zero or infinite resistance means the element is faulty. Replace the element if your reading falls outside the typical range for your model, usually between 10 and 30 ohms.

Is it safe to test a water heater element yourself?

You can safely test the element if you turn off the power at the breaker and verify with a voltage tester. Always wear insulated gloves and safety glasses for extra protection.

What tools do you need to test a water heater element?

You need a digital multimeter, a screwdriver, and insulated gloves. Optional tools include a heating element wrench and a voltage tester for added safety.

Why does your water heater element fail so often?

Hard water, sediment buildup, and corrosion cause frequent element failures. Regular maintenance, such as flushing the tank and checking the anode rod, helps extend the element’s lifespan.

Can a faulty element cause high energy bills?

Yes. A faulty or partially working element forces your water heater to run longer, which increases energy consumption and raises your utility bills.

Should you replace both elements at the same time?

You do not need to replace both elements unless both show signs of failure. If one fails and the other is old or corroded, replacing both can prevent future issues.