The secret to next-generation thermal technology is out. The future lies in 3D-printed stainless steel. Heating element manufacturers, including pioneers like Jinzhong Electric Heating, are revolutionizing household appliance heating elements with this method. The additive process creates a single-piece heating element with complex internal geometries, something previously impossible.

This innovation unlocks a new era of performance. It delivers faster heating, superior energy efficiency, and unmatched product longevity. 🚀

The Old Way vs. The New Secret: A Manufacturing Revolution

To appreciate the leap forward in 2025, one must first understand the limitations of the past. The difference between a traditional heating element and a 3D-printed one is not just an upgrade; it is a fundamental shift in design philosophy and manufacturing capability.

The Limitations of Traditional Manufacturing

Bending, Welding, and Inherent Weak Points

Traditional manufacturing relies on subtractive and formative methods. Technicians take a straight tube of metal, bend it into a basic shape, and weld components like flanges and terminals onto it. This multi-part assembly process introduces numerous structural vulnerabilities. These weak points are the primary sources of failure.

- Mechanical Stress: Repeated heating and cooling causes expansion and contraction, leading to microcracks at bends and joints.

- Electrical Failures: Poor connections or insulation breakdown can cause electrical arcing, a major fire hazard.

- Corrosion: Welded seams and joints are highly susceptible to contamination and corrosion, which degrades the material over time.

These issues result in a shorter operational lifespan and a higher risk of malfunction.

Inefficient and Uneven Heat Patterns

The simple, bent-tube shape of a conventional heating element restricts its performance. Heat does not distribute evenly across its surface. This inefficiency creates “hot spots”—areas that become significantly hotter than others. These hot spots accelerate material degradation, waste energy, and lead to inconsistent heating of the target substance, whether it is water in a kettle or air in a dryer.

The 3D Printing Breakthrough

Additive manufacturing, or 3D printing, builds the element layer by layer from a metal powder. This method completely sidesteps the flaws of traditional fabrication.

The Strength of Monolithic (Single-Piece) Design

3D printing creates a single, solid piece of metal with no seams, joints, or welds. This is known as a monolithic design.

By eliminating the welds and mechanical joints found in traditional elements, the monolithic structure removes the most common points of failure. This results in a product with superior structural integrity and durability.

This single-piece construction resists the thermal stress of constant heating and cooling far more effectively than a multi-part assembly.

Engineering Complex Internal Geometries

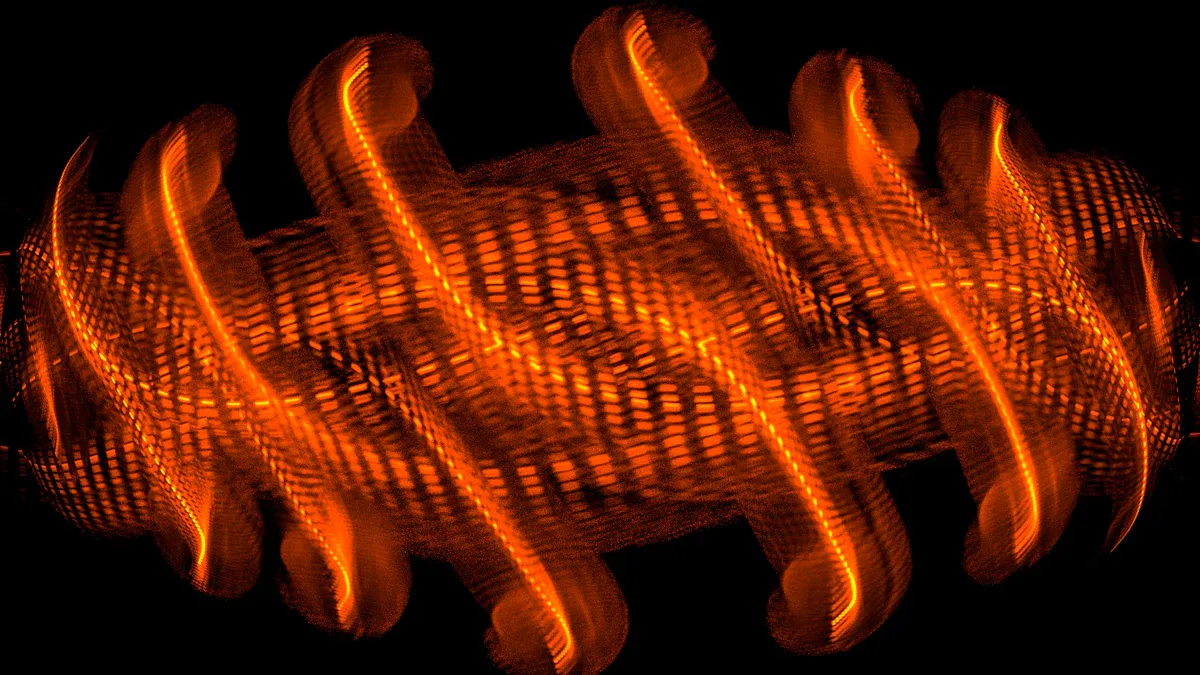

The true secret of this technology lies in its ability to create complex shapes that were previously impossible. Engineers can now design intricate internal channels and pathways within the element itself.

| Feature | Traditional Manufacturing | 3D Printing (Additive) |

|---|---|---|

| Construction | Multi-part (bent, welded) | Monolithic (single-piece) |

| Internal Design | Simple hollow tube | Complex, optimized channels |

| Heat Distribution | Uneven, with hot spots | Precise and uniform |

This level of design freedom allows for the perfect optimization of heat transfer. The element can be engineered to heat fluid or air with maximum efficiency, eliminating hot spots and drastically reducing the time it takes to reach the target temperature.

Unlocking Superior Performance and Efficiency

The shift to additive manufacturing is not just about a new production method; it is about unlocking a level of performance and efficiency that was previously unattainable. The monolithic design and complex geometries of 3D-printed elements directly translate into tangible benefits for both consumers and industries.

Achieving Unmatched Heating Efficiency

Efficiency is the cornerstone of this technological leap. 3D-printed elements use energy more intelligently, converting more electrical power directly into useful heat and minimizing waste.

How Optimized Shapes Distribute Heat

Engineers now use advanced computational fluid dynamics (CFD) to simulate and perfect the flow of liquid or air through an element. This allows them to design intricate internal pathways, such as lattice structures or gyroid cores, that were impossible to create with traditional methods.

These optimized geometries guide the fluid, ensuring it tumbles and swirls to make maximum contact with the heated surfaces. This approach can achieve superior heat transfer even with a smaller surface area because the flow dynamics are structured so effectively. Key benefits include:

- Elimination of Dead Zones: Smart inlet and outlet designs smooth the fluid’s path, preventing stagnant areas where heat transfer is poor.

- Uniform Heating: The complex internal channels distribute heat evenly, eliminating the damaging hot spots common in older designs.

- Increased Power Density: Topology-optimized designs can achieve significantly higher power density. One study showed a 27.6% increase, allowing for more powerful yet compact components.

A prime example is the use of conformal cooling channels. Engineers can design a heating element with internal pathways that perfectly hug the contours of a specific part, reducing operating temperatures by as much as 33% and extending the machine’s lifespan.

Drastically Faster Ramp-Up Times

This incredible efficiency directly translates to speed. When a heating element transfers energy more effectively, the target substance—be it water for your morning coffee or oil in an industrial cooler—reaches its desired temperature much faster.

Less energy is wasted heating the element itself or the surrounding air. More energy goes directly into the task at hand. This results in a dramatic reduction in ramp-up times, a critical performance metric for both home appliances and industrial processes.

| Performance Metric | Traditional Element | 3D-Printed Element |

|---|---|---|

| Energy Transfer | Inefficient, lossy | Highly efficient, direct |

| Ramp-Up Time | Slow | Significantly faster |

| Energy Consumption | Higher | Lower |

A New Standard for Durability

Beyond speed and efficiency, the manufacturing process itself creates a product that is fundamentally stronger and more reliable. Additive manufacturing sets a new benchmark for the operational lifespan of heating components.

Eliminating Failure-Prone Welds and Joints

As discussed, traditional elements fail at their weakest points: the welds, seams, and brazed joints. The monolithic, single-piece construction of a 3D-printed element completely removes these vulnerabilities.

There are no seams to crack under thermal stress. There are no joints to corrode or fail. The entire component is a single, continuous piece of high-grade metal, making it inherently more robust.

This design integrity means the element can withstand thousands of heating and cooling cycles without the mechanical fatigue that plagues multi-part assemblies.

Superior Material Integrity and Lifespan

The additive process builds the component layer by layer from a fine metal powder, resulting in a dense and uniform material structure. This method provides superior material integrity compared to bending and welding a metal tube.

This enhanced durability leads to a significantly longer operational lifespan. For example, redesigning a component for a micro-power generator with 3D printing not only improved thermal management but also reduced its weight by 44%. Lighter, stronger, and cooler-running parts last longer and require less maintenance. This leap in durability makes the advanced heating element a smarter long-term investment.

The Power of Advanced Materials in 3D Printing

An excellent heating element design requires an equally advanced material. The manufacturing process is only half of the equation. The other half is the raw material itself. Additive manufacturing unlocks the full potential of high-performance metal alloys, creating components with properties perfectly matched to their application.

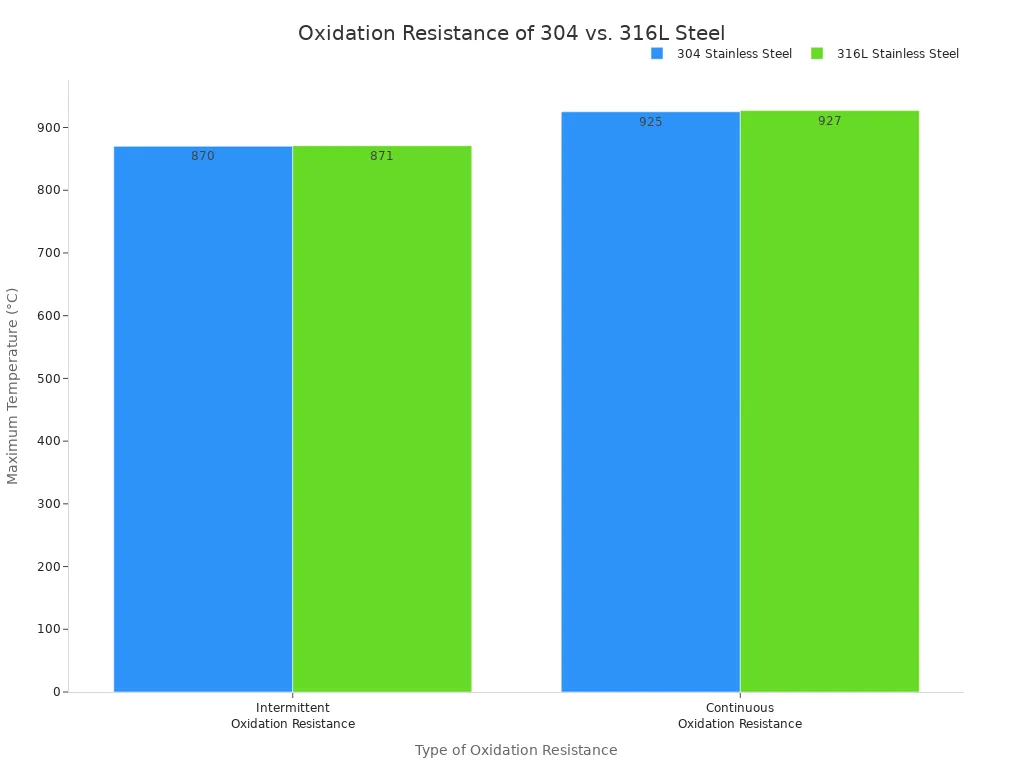

Why the Grade of Stainless Steel Matters

Not all stainless steel is created equal. The specific grade of steel used in a heating element dramatically affects its performance, especially its resistance to heat and corrosion.

316L for Superior Corrosion Resistance

For most consumer and commercial applications, 316L stainless steel is the gold standard. It contains molybdenum, an element that significantly enhances its resistance to chlorides and other corrosive agents. This makes it ideal for water heaters and food-grade equipment. While 304 stainless steel offers good heat resistance, 316L provides a superior defense against corrosion, a key factor in longevity.

The “L” in 316L signifies low carbon content. This property makes it exceptionally well-suited for the welding-free 3D printing process, preventing carbide precipitation and maintaining corrosion resistance throughout the entire monolithic part.

Inconel for Extreme Temperature Stability

When an application involves extreme heat or aggressive chemicals, even 316L stainless steel may not be enough. In these demanding industrial scenarios, engineers turn to superalloys like Inconel.

Inconel is the preferred material for air-critical components with high-temperature needs. It maintains its structural strength and corrosion resistance at temperatures where stainless steel would fail.

This makes Inconel the ideal choice for specialized industrial heaters, aerospace components, and chemical processing equipment where reliability under extreme conditions is non-negotiable.

How 3D Printing Leverages Better Alloys

Additive manufacturing is uniquely suited to working with these advanced materials. The process itself enhances the final properties of the alloy in ways traditional methods cannot.

The Advantages of Powder Metallurgy

3D printing is a form of powder metallurgy. It uses fine, spherical metal powders with a highly controlled chemical composition. This process offers several advantages:

- Homogeneous Structure: The layer-by-layer fusion creates a very dense and uniform (homogeneous) microstructure.

- Reduced Impurities: The controlled environment of the printer minimizes the risk of contamination that can occur during traditional casting or forging.

- Complex Alloy Use: It allows for the use of advanced alloys that are difficult or impossible to shape using conventional bending and welding.

This results in a final part with superior and more consistent material properties than its traditionally manufactured counterpart.

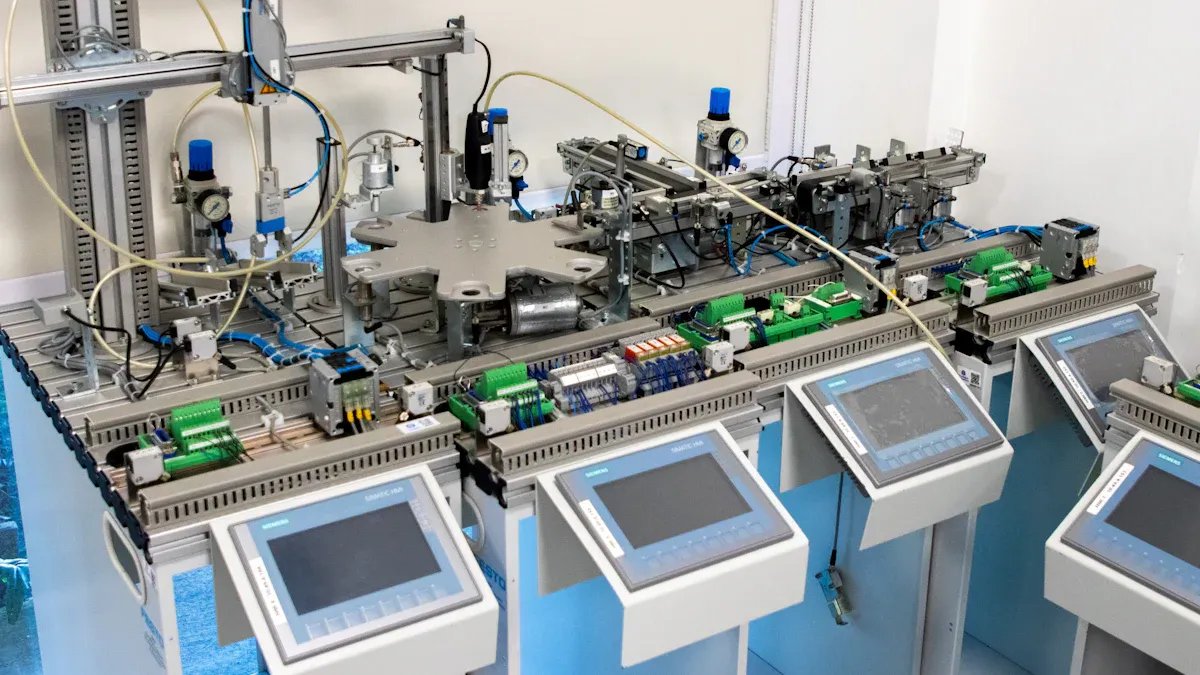

Ensuring Consistent Material Properties

Quality control is paramount in additive manufacturing. To guarantee that every heating element meets exact specifications, manufacturers employ rigorous testing protocols. They develop in-house capabilities to measure the mechanical, metallurgical, and chemical properties of every printed part.

This involves using specialized equipment to verify material integrity. For example, a tensile machine measures a part’s strength and elasticity, while an impact tester evaluates its toughness. By collaborating with reputable suppliers and accredited third-party labs, manufacturers ensure that the material properties are consistent and reliable from the first part to the last.

Customization: The Perfect Fit for Every Application

Beyond raw performance, the greatest advantage of additive manufacturing is its unparalleled design freedom. Traditional manufacturing forces product designers to work around a limited selection of generic heater shapes. 3D printing flips this script, allowing engineers to create a heating element perfectly tailored to the device it serves.

Tailoring Elements for Peak Performance

Customization is not just about aesthetics; it is about maximizing efficiency. By shaping an element to fit a specific application, engineers can optimize every aspect of its performance, from heat distribution to energy consumption.

Elements Shaped to Fit Specific Devices

Additive manufacturing allows for the creation of heaters with intricate patterns that can be integrated into various surfaces and materials, including flexible substrates and 3D objects. This means an element can be designed to perfectly hug the internal contours of a coffee maker’s water chamber or wrap precisely around a complex piece of industrial machinery. This form-fitting approach eliminates the design compromises required by bulky, off-the-shelf components.

Reducing Wasted Space and Energy

When an element fits its application perfectly, it wastes less space and, more importantly, less energy. Complex counter-flow geometries, impossible with traditional methods, maximize the surface area for heat transfer.

This optimization leads to significant efficiency gains. For example, custom-designed heat exchangers built with 3D printing can be up to 30% more efficient than conventional models. This is achieved by creating complex internal channels that maximize heat transfer, reducing overall energy costs.

Real-World Examples of Customization

This technology is already solving challenges across numerous sectors. From compact consumer goods to large-scale industrial equipment, customized printed heaters are delivering precision and efficiency where it matters most.

Compact Elements for Modern Appliances

The ability to create small, intricately shaped heaters has opened new possibilities for appliance manufacturers. These compact elements can be embedded directly into products, a process known as in-mold structural electronics (IMSE®). Real-world applications include:

- Automotive: Heated cup holders, armrests, and battery warmers for electric vehicles.

- Appliances: Frost reduction systems in refrigerator ice dispensers and integrated warming trays.

- Residential: Freeze protection for pipes and other vulnerable components in cold climates.

Specialized Heaters for Industrial Vats

In the industrial world, precision is paramount. Custom 3D-printed heaters address highly specific needs where traditional elements fall short. They are used to maintain exact temperatures in medical incubators and petri dishes, ensuring sample integrity. In the aerospace industry, they keep critical components at efficient working temperatures. They even prevent ice and snow buildup on traffic cameras and solar panels, ensuring continuous and reliable operation.

Your World in 2025: Faster, Smarter, and More Efficient

The theoretical benefits of additive manufacturing are translating into practical, real-world applications. By 2025, this technology will reshape everyday devices and industrial processes. Consumers will experience faster performance at home, while industries will achieve new levels of precision and safety. This shift marks a significant step toward a more efficient future.

The Impact on Home Appliances

Appliance manufacturers are leveraging 3D-printed elements to build the next generation of high-performance products. These components enable designs that are more compact, powerful, and energy-conscious than ever before.

Next-Generation On-Demand Water Heaters

Traditional tankless water heaters often suffer from a “cold water sandwich” effect and bulky size. Additively manufactured elements solve these problems. Their superior power density and rapid ramp-up times allow for smaller, more responsive units. These next-generation heaters provide truly instantaneous hot water, eliminating temperature fluctuations and reducing both energy consumption and water waste.

High-Efficiency Kettles and Coffee Makers

For coffee and tea enthusiasts, temperature control is everything. 3D-printed heating elements offer unparalleled precision. Their optimized internal geometries heat water to an exact temperature with incredible speed.

This means a kettle can reach its boiling point faster while using less electricity. A high-end coffee maker can maintain the perfect water temperature for optimal flavor extraction, delivering a better-tasting beverage every time. ☕

Revolutionizing Commercial and Industrial Sectors

The impact of this technology extends far beyond the home. Commercial and industrial operations are seeing transformative gains in efficiency, safety, and product quality.

Precision Heating in Food Processing

In the food and beverage industry, consistent heating is critical for safety and quality. Traditional elements with hot spots can scorch products, leading to waste and inconsistent batches. Custom 3D-printed elements provide perfectly uniform heat distribution. This precision ensures that products like sauces, dairy, and beverages are heated evenly, preserving flavor and guaranteeing food safety standards are met.

Efficiency Gains in Chemical Manufacturing

Chemical manufacturing involves volatile substances and extreme conditions where equipment failure is not an option. Additive manufacturing provides a solution for creating robust, specialized components. For example, engineers now fabricate 3D-printed calorimeters from stainless steel for process safety analysis. These devices offer several key advantages:

- They can endure harsh reaction conditions, including high pressures and corrosive organic solvents.

- The durable, monolithic design enables the safe use of highly reactive compounds.

- They provide vital safety data, like enthalpy of reaction and heat capacity, for scaling processes safely and efficiently.

This capability allows chemical plants to operate more safely while optimizing their production processes for greater efficiency.

Choosing Your Advanced Stainless Steel Heating Element

Navigating the market for next-generation components requires a new set of knowledge. As 3D-printed technology becomes more prevalent in 2025, informed buyers will need to know what to look for and what to ask. A smart purchasing decision hinges on understanding key terminology and demanding transparent performance data.

A Buyer’s Checklist for the Future

A forward-thinking buyer should approach a purchase with a clear checklist. This ensures the product leverages true additive manufacturing benefits rather than just clever marketing. The focus should be on the manufacturing method and the material quality.

Key Terms: “Additive,” “3D-Printed,” “Monolithic”

Buyers should actively search for specific terms on product descriptions and data sheets. These words signal a departure from traditional, failure-prone manufacturing methods.

Look for keywords like

additive,3D-printed, andmonolithic. These terms indicate the component is a single, solid piece created layer by layer, which is the source of its superior strength and efficiency.

The presence of these terms is the first sign that a product belongs to the new generation of heating technology.

The Importance of Verifying the Steel Grade

The material is just as important as the manufacturing process. Buyers must confirm the grade of stainless steel used, such as 316L for its excellent corrosion resistance. Manufacturers should provide a detailed data sheet with key specifications. While every component is different, a data sheet offers a clear look at the product’s capabilities.

| Specification | Details |

|---|---|

| Dimensions | 214 mm x 214 mm |

| Operating Voltage | 12V or 24V |

| Power Rating | 120W / 240W |

| Material Grade | 316L Stainless Steel |

| Temperature Range | Up to 120°C |

| Connector Type | Solder pads |

| Mounting Holes | 4 holes |

Critical Questions to Ask Manufacturers

Beyond the data sheet, a proactive buyer should engage directly with manufacturers. Asking pointed questions about their process and performance validation separates the true innovators from the rest.

Inquiring About the Manufacturing Process

One should ask about the specific additive manufacturing technology used, such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). It is also wise to inquire about the quality control protocols in place. Reputable manufacturers will be transparent about how they ensure material consistency and part integrity from one batch to the next.

Requesting Comparative Performance Data

To truly gauge the value of an advanced heating element, a buyer should request performance data that compares it to traditional designs. Key metrics validate the quality of a 3D-printed part.

- Density and Porosity: These metrics are crucial for 3D-printed parts. High density and low porosity indicate a solid, well-fused part without internal voids.

- Surface Finish: A controlled surface roughness affects performance factors like fluid dynamics and fatigue resistance.

- Strength: Data on tensile strength and yield strength confirms the part’s mechanical robustness.

- Elongation: This shows how much the material can stretch before breaking, indicating its ductility.

Requesting this data empowers a buyer to make a decision based on proven engineering, not just marketing claims.

The Cost vs. Benefit Analysis for 2025

A prudent analysis of any new technology weighs its initial cost against its long-term benefits. Additively manufactured heating elements present a clear case where the upfront investment delivers substantial returns over time. For buyers in 2025, understanding this balance is key to making a smart financial decision.

Understanding the Initial Investment

The initial purchase price of an advanced component is often the first consideration for a buyer. While 3D-printed elements carry a higher price tag today, this cost reflects the sophisticated nature of the technology.

The Current Price Point of New Technology

The higher initial cost of 3D-printed heating elements stems from several factors. The process requires highly specialized equipment, premium-grade metal powders like 316L or Inconel, and significant engineering expertise to design and validate each part. These inputs contribute to a price point that is currently above that of traditional, mass-produced components.

How Economies of Scale Will Lower Costs

History shows that the cost of innovative technology decreases as it matures. As demand for additively manufactured elements grows, production volumes will increase. This leads to economies of scale, where manufacturers can purchase raw materials in bulk and refine their processes for greater efficiency. These advancements will steadily lower the price, making this superior technology more accessible to a wider market.

Calculating Long-Term Value and ROI

The true value of a 3D-printed heating element becomes apparent when looking at its total cost of ownership. The return on investment (ROI) is driven by significant savings in energy consumption and maintenance.

Projecting Your Energy Savings

The superior efficiency of a 3D-printed element directly translates into lower energy bills. Its optimized design heats substances faster and more uniformly, consuming less electricity to perform the same task. Buyers can estimate these savings using various online tools.

- Organizations like NATE and government sites like energy.gov provide calculators for general energy savings.

- Manufacturers such as AirEase offer tools to compare the efficiency of different heating products.

- Companies like ServiceTitan provide calculators that quantify savings based on furnace efficiency ratings (AFUE).

These resources help quantify the financial benefits of upgrading to a high-efficiency component.

Factoring in Reduced Maintenance and Replacement

Durability is a major component of long-term value. The monolithic design of 3D-printed elements eliminates the welds and joints that are the primary failure points in traditional parts.

This inherent strength drastically reduces the need for costly repairs and premature replacements. Over the lifespan of an appliance or industrial machine, the savings from avoided maintenance calls and component replacements can easily surpass the initial price difference.

This makes the advanced element a financially sound investment in operational reliability and long-term performance.

The future of heating technology has arrived, driven by the innovation of 3D-printed stainless steel elements. This technology delivers a powerful combination of superior efficiency, enhanced durability, and unprecedented customization. It represents a fundamental shift in thermal performance.

For their next purchase, buyers should seek out terms like

additively manufacturedor3D-printed. This ensures an investment in long-term savings and top-tier performance.

FAQ

What is a 3D-printed heating element?

It is a component built layer by layer from metal powder. This additive process creates a single, solid part with complex internal channels. The design eliminates the weak points found in traditional, multi-part elements.

Are these elements more expensive?

They currently have a higher initial cost due to advanced equipment and materials. However, their long-term value comes from significant energy savings and reduced maintenance needs. Economies of scale will also lower prices over time.

Why is a “monolithic” design better?

A monolithic design is a single, solid piece without welds or joints. This structure eliminates the most common points of failure. It provides superior durability against thermal stress and corrosion for a longer operational lifespan.

What materials are used for these elements?

Manufacturers typically use high-performance alloys. 316L stainless steel offers excellent corrosion resistance for most applications. For extreme heat or harsh environments, superalloys like Inconel provide unmatched stability and strength.

How do 3D-printed elements save energy?

Their optimized internal shapes transfer heat more effectively. This superior efficiency reduces ramp-up times and minimizes wasted energy. The element heats the target substance, not the surrounding environment, leading to lower electricity consumption. ⚡

Where will people see this technology in 2025?

This technology will appear in next-generation home appliances like on-demand water heaters and coffee makers. It also revolutionizes industrial sectors, enabling precision heating in food processing and chemical manufacturing for improved safety and efficiency.

How can a buyer identify an advanced element?

Buyers should look for specific keywords on product data sheets.

Key terms include

additive,3D-printed, andmonolithic. Verifying the material grade, such as 316L stainless steel, is also a critical step for ensuring quality.