You see rapid changes in 2025 trends for dryer heating elements. New heat pump technology lets you lower utility costs and dry clothes faster. Smart controls predict maintenance needs and optimize load performance, giving you a better experience with dryers. Sustainability drives demand for eco-friendly solutions, supporting corporate responsibility and reducing carbon footprints. Jinzhong Electric Heating and other heating element manufacturers lead innovation in household appliance heating elements, making your next dryer more efficient and reliable.

Breakthrough Materials Shaping 2025 Trends in Dryer Heating Elements

Advanced Alloys for Enhanced Efficiency

High-Performance Nickel-Chromium Blends

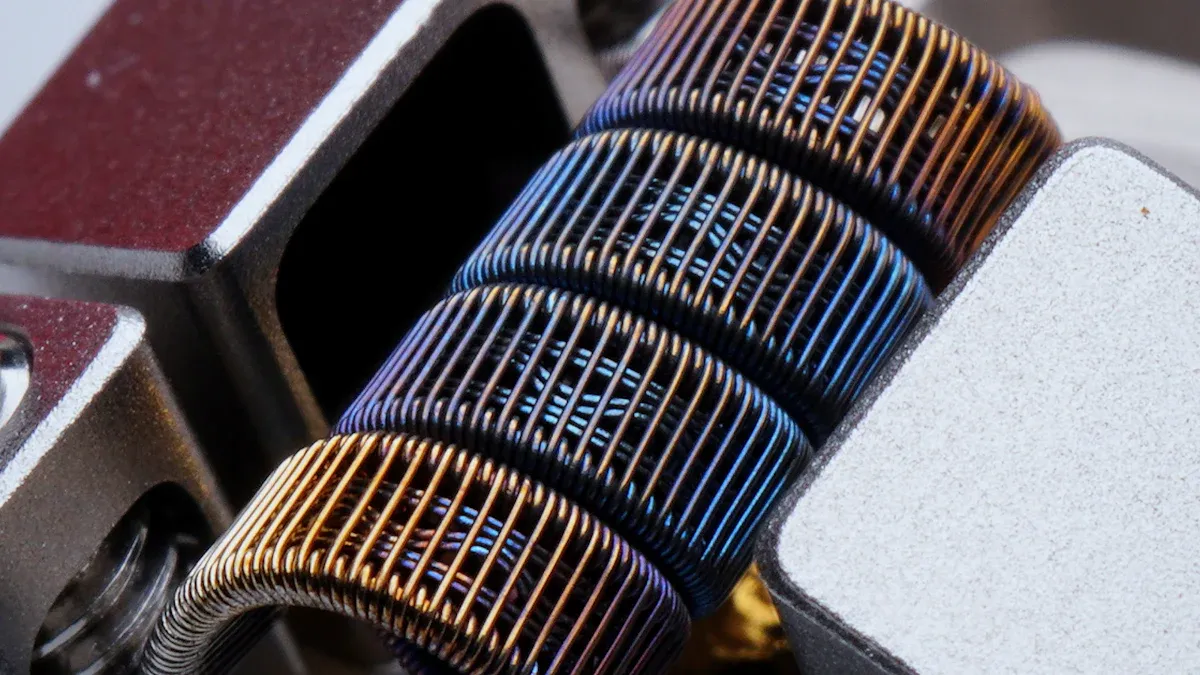

You see high-performance nickel-chromium blends leading the heating element core market in 2025 trends. These alloys deliver superior thermal conductivity and resist oxidation at high temperatures. When you use dryers with these electric heating elements, you benefit from faster heat-up times and consistent temperature control. Nickel-chromium blends also reduce energy waste, which boosts efficiency and supports sustainability goals. Manufacturers choose these advanced materials because they extend the lifespan of heaters and lower maintenance needs.

Corrosion-Resistant Coatings for Longevity

You want your dryer to last longer and perform reliably. Corrosion-resistant coatings protect electric heating elements from moisture and chemical exposure. These coatings form a barrier that prevents rust and degradation, even in demanding environments. As a result, you experience fewer breakdowns and enjoy a more dependable appliance. The heating element core market now prioritizes these coatings to meet the demands of modern dryers and ensure long-term value.

Ceramic-Based Heating Elements in Modern Dryers

Rapid-Heating Ceramics for Faster Drying

Ceramic-based electric heating elements have become a game-changer for dryers. You notice that these elements heat up quickly and distribute warmth evenly. Rapid-heating ceramics cut drying times and help you save energy. The heating element core market recognizes ceramics as a key driver of efficiency and performance. When you select a dryer with ceramic heaters, you gain the advantage of faster cycles and lower utility bills.

Enhanced Durability and Extended Lifespan

You expect your appliances to withstand daily use. Ceramic electric heating elements offer exceptional durability. They resist thermal shock and maintain structural integrity under repeated heating and cooling cycles. This resilience means you replace elements less often, which reduces waste and supports sustainability. The heating element core market values ceramics for their ability to deliver long-lasting performance in modern dryers.

Composite Materials Driving Efficiency in Dryers

Lightweight, High-Efficiency Composites

Composite materials now shape the future of electric heating elements. You benefit from lightweight construction, which makes dryers easier to install and move. These composites combine strength with low mass, improving energy transfer and reducing overall power consumption. The heating element core market sees composites as essential for meeting efficiency targets and supporting the latest trends in appliance design.

Improved Thermal Conductivity for Better Heating

You want your dryer to deliver consistent results every time. Composites with enhanced thermal conductivity ensure that electric heating elements reach optimal temperatures quickly and maintain steady heat output. This improvement leads to better drying performance and less wear on heaters. The heating element core market continues to invest in advanced materials that maximize efficiency and reliability.

Tip: When you choose a dryer with advanced materials in its electric heating elements, you invest in efficiency, durability, and long-term savings.

| Material Type | Key Benefit | Impact on Dryers |

|---|---|---|

| Nickel-Chromium | High thermal conductivity | Faster, efficient heating |

| Ceramics | Rapid heat-up, durability | Shorter cycles, longevity |

| Composites | Lightweight, efficient | Easy handling, energy savings |

Emerging Materials and Innovations for 2025

Graphene-Infused Heating Elements

You now see graphene making a strong impact on dryer heating technology. Graphene stands out as one of the most conductive materials available. When you use graphene-infused heating elements, you benefit from rapid heat transfer and precise temperature control. This material allows your dryer to reach optimal temperatures faster, which means shorter drying cycles and less energy wasted.

Graphene’s structure gives it remarkable strength and flexibility. You get a heating element that resists wear and tear, even after many cycles. Manufacturers use graphene to create thinner, lighter components. This approach reduces the overall weight of your dryer and improves energy efficiency.

Note: Graphene-infused heating elements represent a leap forward in advanced materials. You gain both performance and durability, which aligns with the latest 2025 trends in appliance design.

| Feature | Benefit to You |

|---|---|

| High thermal conductivity | Faster drying, less energy use |

| Thin, flexible design | Lightweight, compact dryers |

| Exceptional durability | Fewer replacements needed |

Carbon Nanotube and Phase-Change Material Applications

You also encounter carbon nanotubes and phase-change materials as key innovations in dryer heating elements. Carbon nanotubes offer unique electrical and thermal properties. When you use heating elements with carbon nanotubes, you experience even heat distribution and improved reliability. These nanotubes help your dryer maintain consistent temperatures, which protects your clothes and boosts efficiency.

Phase-change materials add another layer of innovation. These materials absorb and release heat as they change state. You benefit from stable drying temperatures and reduced risk of overheating. This technology helps your dryer adapt to different fabric types and load sizes, giving you more control over the drying process.

-

Carbon nanotube heating elements provide:

- Superior heat management

- Enhanced safety features

- Longer operational life

-

Phase-change materials deliver:

- Temperature stability

- Energy savings

- Protection for delicate fabrics

You see these advanced materials driving new trends in dryer technology. Manufacturers focus on combining performance, safety, and sustainability. As a result, you get a dryer that meets your needs today and adapts to future demands.

Next-Generation Technologies Transforming Dryer Heating

Smart Controls and Sensor Integration in Dryers

Adaptive Heating Algorithms for Optimal Performance

You experience a new level of control with adaptive heating algorithms in modern dryers. These algorithms analyze real-time data from electric heating elements and adjust the drying cycle for optimal results. You benefit from precise temperature management, which protects fabrics and improves efficiency. The heating element core market now focuses on self-regulating heaters that respond to moisture and load size. This approach ensures that you get consistent drying without wasting energy.

The sensor continuously communicates with the dryer controller, adjusting drying parameters based on real-time moisture readings, ensuring optimal drying efficiency.

Pressure sensors monitor airflow behind the lint screen. You receive alerts when it is time to clean the lint filter, which reduces energy consumption and prevents fire hazards. Advanced moisture sensors detect when clothes are dry, stopping the cycle to avoid overdrying and fabric damage. Safety sensors add another layer of protection by identifying lint buildup and warning you before problems occur.

- Energy Star-certified dryers significantly reduce energy consumption and carbon footprint.

- Advanced moisture sensors accurately detect moisture levels, preventing overdrying and fabric damage.

- Safety sensors that detect lint buildup can alert users to potential fire hazards, enhancing safety.

Real-Time Performance Monitoring and Feedback

You gain valuable insights with real-time performance monitoring in electric heating elements. The dryer tracks temperature, humidity, and airflow, then displays feedback on the control panel or your mobile device. You see exactly how your dryer operates, which helps you optimize each load. The heating element core market invests in smart controls that provide instant feedback, allowing you to adjust settings for better results.

You can monitor the health of electric heating elements and heaters, reducing maintenance needs and extending appliance lifespan. Self-regulating heaters automatically adjust power output to maintain consistent heat, which improves safety and reliability. You stay informed about the status of your dryer and can act quickly if any issues arise.

IoT and Connectivity: Market Trends 2025

Remote Diagnostics and User Control via Wi-Fi

You control your dryer from anywhere using Wi-Fi connectivity. This feature lets you start, stop, or adjust cycles remotely, giving you flexibility and convenience. The heating element core market now supports remote diagnostics, so you receive alerts about electric heating elements and heaters before problems develop. You save time and avoid unexpected breakdowns.

- Wi-Fi Connectivity allows remote monitoring and control of the dryer, enhancing user convenience.

- Real-Time Adjustments enable dryers to change drying cycles based on moisture levels, optimizing performance.

- Eco-Friendly Modes adjust drying times and temperatures based on load size, improving energy efficiency.

You see a growing trend toward integrating smart technology and IoT connectivity in dryer heating elements. Smart heating elements allow for remote temperature management, predictive maintenance, and energy optimization. The market shifts toward sustainable manufacturing practices and expands applications in renewable energy and electric mobility.

Predictive Maintenance Enabled by AI and IoT

You benefit from predictive maintenance powered by AI and IoT. The dryer analyzes data from electric heating elements and heaters, then predicts when maintenance is needed. You receive notifications before issues become serious, which reduces downtime and repair costs. The heating element core market adopts AI-driven solutions to improve reliability and extend the lifespan of electric heating elements.

You see innovation in self-regulating heaters that adjust their operation based on usage patterns. This technology helps you avoid unnecessary repairs and ensures that your dryer operates at peak efficiency. You experience fewer interruptions and enjoy a more dependable appliance.

Heat Pump Technology and Hybrid Heating Systems

Energy-Efficient Heat Pump Dryers

You achieve significant energy savings with heat pump dryers. These dryers use a closed-loop system that moves heat instead of generating it, which makes them much more efficient than conventional models. Electric heating elements work with refrigerant lines and coils to transfer heat efficiently. You do not need external venting, so heat stays inside your home.

- Heat pump dryers warm, cool, and condense the same air within a self-contained system.

- They use refrigerant lines and coils to transfer heat efficiently.

- Energy savings can reach up to 60% compared to conventional electric dryers.

| Type of Dryer | Energy Usage Reduction |

|---|---|

| Heat Pump Dryer | Up to 60% less energy |

| Conventional Dryer | Baseline energy usage |

Heat pump dryers extract moisture using a refrigerant and condenser, rather than generating heat with gas or electric coils. This method resembles an air conditioner in reverse, which enhances energy efficiency. You see the heating element core market investing in energy-efficient technologies to meet 2025 trends and reduce environmental impact.

Hybrid Heating Systems for Versatile Applications

You find hybrid heating systems combining electric heating elements with heat pump technology. These systems offer versatile applications for different load sizes and fabric types. You get the benefits of rapid heating from electric heating elements and the energy savings of heat pump dryers. The heating element core market develops hybrid solutions to meet diverse consumer needs and support energy-efficient solutions.

You experience improved performance and flexibility with hybrid systems. Self-regulating heaters work alongside heat pumps to maintain optimal temperatures and protect delicate fabrics. You see innovation driving the adoption of hybrid heating systems in the latest dryers.

Tip: Choose dryers with advanced electric heating elements and hybrid systems to maximize energy savings and performance.

Innovative Heating Methods in 2025 Dryers

Microwave-Assisted Drying Technology

You see microwave-assisted drying emerging as a leading innovation in the heating element core market. This technology uses microwaves to excite water molecules within fabrics, causing them to evaporate rapidly. You experience shorter drying cycles and improved energy efficiency compared to conventional electric heating methods. Manufacturers design these systems to target moisture directly, which reduces the risk of overdrying and fabric damage.

Microwave-assisted heating offers several advantages:

- Faster moisture removal from clothes

- Lower energy consumption per cycle

- Enhanced protection for delicate fabrics

You notice that microwave-assisted dryers use sensors to monitor moisture levels in real time. These sensors adjust the heating intensity, ensuring optimal drying without wasting energy. You benefit from precise control over drying cycles, which supports sustainability goals and aligns with 2025 trends in appliance design.

Tip: Microwave-assisted drying reduces wear on fabrics and helps you save on utility costs.

Ultrasonic Drying for Enhanced Efficiency

You encounter ultrasonic drying as another breakthrough in dryer heating technology. Ultrasonic systems use high-frequency sound waves to create vibrations that separate water from fabric fibers. You see water droplets forming and leaving the clothes without the need for high temperatures. This method delivers efficient drying while preserving fabric quality.

Ultrasonic heating provides several key benefits:

- Lower operating temperatures, which protect sensitive materials

- Reduced energy usage compared to traditional heating elements

- Quieter operation, making your laundry experience more pleasant

You find that ultrasonic dryers integrate smart controls to optimize drying cycles. These controls monitor fabric type and moisture content, adjusting the ultrasonic intensity for best results. You enjoy faster drying times and improved energy efficiency, which supports your commitment to sustainability.

Note: Ultrasonic drying represents a major step forward in the heating element core market, offering both performance and eco-friendly advantages.

| Innovative Method | Effectiveness | Source |

|---|---|---|

| Heat Pump Technology | Improved energy efficiency and reduced drying times | Zhang et al. |

| Combined Heat Pump and Fluidized Bed | Reduced energy consumption and enhanced drying speed | Zielinska et al. |

| Heat Pump with Vacuum Freeze-Drying | High-quality results with shorter drying time | Wang et al. |

You see manufacturers investing in advanced heating methods to meet the demands of 2025 trends. These innovations help you achieve better drying performance, lower energy costs, and improved sustainability. You gain access to dryers that combine microwave, ultrasonic, and heat pump technologies for optimal results.

Sustainability and Eco-Friendly Advances in Dryer Heating Elements

Eco-Conscious Manufacturing and Market Trends 2025

Reduced Carbon Footprint in Production Processes

You see manufacturers in the heating element core market adopting eco-friendly manufacturing to reduce carbon emissions. Companies now use advanced electric heating elements that require less energy during production. You benefit from lower environmental impact when you choose dryers built with these sustainable practices. The heating process uses less fossil fuel, which supports global sustainability initiatives and aligns with 2025 trends.

Use of Recycled and Sustainable Materials

You notice a shift toward recycled and sustainable materials in electric heating elements. Manufacturers select 304 stainless steel casings for heaters because they are 100% recyclable and corrosion-resistant. You get dryers with modular components, which means over 90% of the material can be recycled at the end of the product’s life. This approach supports sustainable technology integration and helps you contribute to sustainability by choosing appliances designed for recyclability.

| Feature | Contribution to Sustainability |

|---|---|

| 304 stainless steel casings | 100% recyclable and corrosion-resistant |

| Modular components | 90%+ material recyclability at end-of-life |

| Closed-loop recycling programs | Ensure zero landfill waste |

Recyclability and End-of-Life Solutions for Dryers

Modular Design for Easy Disassembly and Recycling

You benefit from modular design in electric heating elements. Manufacturers create heaters and elements that you can easily disassemble, making recycling more efficient. You see the heating element core market prioritizing modularity to support sustainability initiatives. This design reduces waste and simplifies the recycling process for dryers.

Closed-Loop Recycling Programs in the Industry

You find closed-loop recycling programs gaining traction in the heating element core market. Manufacturers, governments, and recycling facilities work together to improve infrastructure. You see takeback programs for old dryers, which ensure proper recycling and minimize environmental impact. Extended Producer Responsibility policies hold manufacturers accountable for the entire lifecycle of electric heating elements and heaters. You support sustainability when you choose dryers from brands that participate in these programs.

- Collaboration among governments, recycling facilities, and manufacturers enhances recycling infrastructure.

- Takeback programs for old dryers ensure proper recycling and reduce environmental impact.

- Extended Producer Responsibility policies promote sustainable design and recycling practices.

Energy Efficiency Standards and Regulatory Compliance

Meeting 2025 Efficiency Regulations for Dryers

You must consider new energy efficiency standards for electric heating elements in dryers. The heating element core market responds to regulatory changes by improving energy savings and reducing consumption. You see products meeting recommended TSL efficiency levels for electric standard, electric compact, vented electric compact, and vented gas standard clothes dryers. These regulations take effect March 1, 2028, but manufacturers already design elements and heaters to comply with future requirements.

| Compliance Date | Efficiency Level | Product Class |

|---|---|---|

| March 1, 2028 | Recommended TSL | Electric standard, electric compact, vented electric compact, vented gas standard clothes dryers |

Impact on Utility Costs and Environmental Footprint

You experience lower utility costs when you use dryers with advanced electric heating elements. Improved energy savings and efficient heaters reduce your monthly bills. You also help decrease the environmental footprint by choosing products that meet strict efficiency standards. The heating element core market continues to innovate, ensuring that you get reliable performance and support sustainability.

Tip: Select dryers with high-efficiency electric heating elements and modular design to maximize energy savings and support eco-friendly manufacturing.

Performance and User Experience Improvements in 2025 Dryers

Faster Drying Times and Enhanced Heating Distribution

Optimized Airflow and Heat Management

You notice that new dryers in 2025 deliver faster drying times and improved heating distribution. Manufacturers optimize airflow by redesigning vents and channels, allowing heated air to reach every part of the drum. You benefit from advanced heating elements that maintain consistent temperatures, reducing the risk of uneven drying. Digital controls and smart sensors work together to adjust heating output, ensuring that each load receives the right amount of heat. This approach boosts performance and efficiency, helping you save time and energy.

| Evidence Type | Description |

|---|---|

| Energy Efficiency | Advancements in heat pump dryer technology in 2025 lead to improvements in energy efficiency and performance. |

| Faster Drying Times | Studies document measurable improvements in drying times, indicating that new models are becoming more effective. |

| Better Heating Distribution | Integration of advanced digital controls and smart features enhances process efficiency and drying performance. |

Advanced Drum and Element Design

You experience the benefits of advanced drum and heating element design. Manufacturers use precision engineering to create drums that rotate smoothly and distribute clothes evenly. Heating elements now feature improved placement and structure, allowing heat to reach every item in the load. You see fewer cold spots and more consistent results. These innovations make your dryer more reliable and help protect delicate fabrics from overheating.

Durability, Reliability, and Reduced Maintenance

Extended Heating Element Lifespan

You expect your dryer to last for years. In 2025, heating elements use robust materials and improved construction methods to extend their lifespan. You find that brands like Samsung and Maytag offer elements with impressive durability. Samsung heating elements typically last between 8 and 14 years, while Maytag elements often reach 15 years or more. You benefit from fewer replacements and less downtime.

| Brand | Average Lifespan | Reliability | Value for Money |

|---|---|---|---|

| Samsung | 10–14 years | Good, varies by model | Strong with maintenance |

| Maytag | 15+ years | Heavy-duty, consistent | Slight edge due to durability |

- Samsung dryer heating elements typically last between 8 and 14 years under normal use.

- Maytag dryer heating elements often last 15 years or longer due to robust construction.

- Users report that Maytag dryers maintain a more stable temperature, reducing heating issues.

Lower Maintenance Requirements for Users

You appreciate lower maintenance requirements in modern dryers. Heating elements now resist wear and tear, reducing the need for frequent servicing. You spend less time on upkeep and more time enjoying reliable performance. Manufacturers design elements for easy access, making cleaning and replacement straightforward. You save money and avoid unexpected repairs.

Safety Enhancements in Modern Dryer Heating

Overheat Protection and Smart Safety Systems

You gain peace of mind with new safety features in dryer heating elements. Overheat protection systems monitor temperature and shut down the dryer if levels rise too high. Smart sensors detect potential hazards, such as lint buildup or blocked vents, and alert you before problems occur. You reduce the risk of fire and protect your home.

Child and Pet Safety Features in 2025 Dryers

You see manufacturers prioritizing child and pet safety in 2025 dryers. Heating elements now include shields and barriers to prevent accidental contact. Locking mechanisms keep doors secure during operation. You feel confident that your dryer operates safely, even in busy households.

| Feature | Description |

|---|---|

| Intelligent Sensor Technology | Automatically adjusts heat to minimize damage and enhance hair shine. |

| Scalp Protect Mode | Regulates temperature based on proximity to the scalp to prevent overheating. |

| User-Friendly Features | Enhancements aimed at optimizing user experience and hair health. |

Tip: Choose dryers with advanced heating elements and smart safety systems to maximize durability, performance, and peace of mind.

Comparing Top Materials and Technologies for Dryer Heating Elements

Alloys vs. Ceramics vs. Composites: Efficiency and Performance

Heat Output and Energy Consumption

You face many choices when selecting dryer heating elements. Alloys, ceramics, and composites each offer unique benefits for heat output and energy consumption. Ceramic heating elements deliver high energy efficiency and precise temperature control. You find these elements best for high-temperature applications. Stainless steel heating elements provide durability and versatility. You see good efficiency and added durability with these elements. Composites combine lightweight construction with improved thermal conductivity, helping you achieve consistent heating and lower energy use.

| Heating Element Type | Efficiency Characteristics | Performance Notes |

|---|---|---|

| Ceramic Heaters | High energy efficiency, ideal for precise temperature control | Best for high-temperature applications |

| Stainless Steel | Durable and versatile, suitable for various applications | Good efficiency with added durability |

Cost, Availability, and Application Suitability

You consider cost and availability when choosing heating elements. Stainless steel elements remain widely available and affordable. Ceramic elements cost more but offer longer lifespans and better performance in demanding environments. Composites present a balance between cost and advanced features. You select elements based on your budget and the specific needs of your dryer. Each type suits different applications, from residential to commercial use.

Smart Heating Elements vs. Traditional Systems

User Control, Automation, and Customization

You experience greater control with smart heating elements compared to traditional systems. Smart elements allow you to set different temperatures at various times. You access your dryer remotely using apps. These elements learn your routines and adjust automatically. You enjoy a personalized drying experience with advanced automation.

Smart HVAC systems provide enhanced functionality compared to traditional systems, allowing for different temperature settings at various times, remote access via apps, and the ability to learn user routines for automatic adjustments. This level of user control and automation is a significant advancement over traditional systems.

Maintenance, Troubleshooting, and Longevity

You benefit from easier maintenance and troubleshooting with smart heating elements. These elements monitor their own performance and alert you to potential issues. You spend less time on repairs and replacements. Traditional elements require manual checks and more frequent servicing. Smart elements extend the lifespan of your dryer and reduce downtime.

Sustainability Trade-Offs in 2025 Trends

Environmental Impact of Different Materials

You weigh the environmental impact when selecting heating elements. Ceramic and composite elements often use less energy and produce fewer emissions during operation. Stainless steel elements offer recyclability, supporting sustainability goals. You choose elements that align with your commitment to sustainability and environmental responsibility.

Long-Term Value and Lifecycle Considerations

You look for long-term value in dryer heating elements. Ceramic elements last longer and require fewer replacements. Stainless steel elements provide reliable performance over many years. Composites offer a balance of durability and efficiency. You consider the full lifecycle of each element, from production to disposal, to maximize value and minimize waste.

Market Trends 2025 and Regulatory Impacts on Dryer Heating

Rise of Smart Dryers and Connected Appliances

Consumer Demand for Connectivity and Smart Features

You see a surge in demand for smart features in dryers as market trends 2025 shape the future of home appliances. Consumers now expect seamless connectivity, remote control, and real-time feedback from their devices. The market for smart appliances is projected to reach $43.55 billion in 2025, with strong growth anticipated through 2032. In the U.S., the home smart washers and dryers segment was valued at $1.5 billion in 2022 and is forecasted to hit $4.0 billion by 2030. Globally, the smart washers and dryers market will expand from $6.31 billion in 2025 to $55.1 billion by 2033. You benefit from features like app-based control, energy monitoring, and predictive maintenance, which enhance convenience and efficiency.

Integration with Home Automation Ecosystems

You experience greater integration between dryers and home automation systems. Manufacturers design heating elements and controls to work with smart home platforms, allowing you to automate laundry routines and optimize energy use. You can link your dryer to voice assistants, schedule cycles, and receive maintenance alerts. This level of connectivity supports sustainability and aligns with the latest technology trends in the commercial dryer market.

Regulatory Changes and Efficiency Standards for 2025

New Energy Efficiency Requirements for Dryers

You must navigate new regulations that impact heating elements and energy consumption in dryers. The Department of Energy (DOE) updates test procedures to ensure products meet current efficiency standards. These reviews occur at least once every seven years and focus on reducing energy waste. Manufacturers respond by improving heating element design and adopting advanced materials.

| Regulatory Change | Description |

|---|---|

| DOE Test Procedures | DOE updates test procedures for clothes washers and dryers to reflect energy efficiency and minimize burden. |

| Compliance Review | DOE reviews test procedures every seven years to ensure standards remain effective. |

Compliance Challenges and Opportunities for Manufacturers

You see manufacturers facing both challenges and opportunities as they adapt to new regulations. High capital investment poses difficulties for small and medium-sized enterprises, especially when upgrading heating technology. Fluctuating energy costs increase operational expenses, requiring careful planning. Legacy systems often need costly retrofitting to meet new standards. Stringent compliance demands ongoing investment in research and development, but technological advancements offer opportunities for efficiency and modernization. Public-private partnerships help drive sustainability and support innovation.

| Challenges/Opportunities | Description |

|---|---|

| High Capital Investment | SMEs struggle with costs of advanced technologies, slowing adoption. |

| Energy Costs | Fluctuating prices require balance between investment and cost-effectiveness. |

| Integration Complexities | Retrofitting legacy systems delays new technology adoption. |

| Stringent Regulatory Compliance | Ongoing R&D and process adjustments needed to avoid penalties. |

| Technological Advancements | New technologies enable efficiency and modernization. |

| Public-Private Partnerships | Collaboration supports modernization and sustainability efforts. |

Industry Response and Future Outlook for Dryer Heating

Investment in R&D and Innovation

You notice leading manufacturers investing heavily in research and development to advance heating technology. Companies focus on integrating sensors and smart diagnostics, developing new materials like ceramics and carbon fiber, and utilizing artificial intelligence for predictive maintenance and energy optimization. R&D efforts address challenges such as raw material supply and regulatory changes. Customization grows in importance, especially for medical and industrial applications.

| Investment Focus | Description |

|---|---|

| Advanced Technologies | Sensors and smart diagnostics for maintenance. |

| New Materials | Ceramics and carbon fiber improve energy efficiency and lifespan. |

| AI Utilization | Predictive maintenance and energy optimization. |

| Market Response | R&D addresses supply and regulatory challenges. |

| Customization | Tailored solutions for medical and industrial uses. |

Anticipated Next-Generation Features and Market Growth

You can expect next-generation features in dryers, such as advanced heating elements, smart controls, and enhanced energy management. The NTC Heating Element market is projected to grow at an annual rate of 9% from 2025 to 2032. This growth is driven by rising demand in automotive, consumer electronics, and HVAC systems. The market includes SMD Type and Through Hole Type segments, serving applications in consumer electronics, medical instruments, automotive, home appliances, industrial equipment, and aerospace & defense. You benefit from improved efficiency, greater sustainability, and ongoing innovation in dryer heating technology.

- The NTC Heating Element market will grow at 9% annually from 2025 to 2032.

- Demand increases in automotive, consumer electronics, and HVAC systems.

- Market segments include SMD Type and Through Hole Type for diverse applications.

You see 2025 trends in dryer heating elements driving major changes in efficiency, sustainability, and performance. Heat pump dryers now cut electricity use by up to 65% and finish cycles in just over half an hour. As you evaluate new dryer technologies, consider these factors:

| Factor | Description |

|---|---|

| Brand Support | Strong support from brands like Maytag and Samsung can aid in troubleshooting and repairs. |

| Durability | Materials like stainless steel enhance longevity, reducing the need for replacements. |

| Efficiency Ratings | Higher efficiency can lead to lower utility bills over time. |

| Compatibility | Ensuring the heating element fits your dryer is crucial to avoid wasted expenses. |

You should also watch for market trends 2025, including rapid advances in smart controls and eco-friendly materials. The market continues to evolve, offering you more reliable, efficient, and sustainable dryers as the market grows.

FAQ

What makes 2025 dryer heating elements more energy efficient?

You benefit from advanced materials like ceramics, composites, and nickel-chromium alloys. These elements heat faster and maintain stable temperatures. Manufacturers optimize airflow and integrate smart controls. You see lower energy consumption and shorter drying cycles.

How do smart controls improve dryer performance?

You use smart controls to monitor moisture, temperature, and airflow. The dryer adjusts settings automatically for each load. You receive alerts for maintenance and safety. This technology helps you achieve consistent results and protects your fabrics.

Are new dryer heating elements safer for homes with children or pets?

You gain peace of mind with enhanced safety features. Manufacturers add shields, locking doors, and smart sensors. These systems prevent accidental contact and detect hazards. You protect your family and pets from overheating or fire risks.

Can you recycle modern dryer heating elements?

You support sustainability by choosing dryers with modular designs and recyclable materials. Manufacturers use stainless steel and composites that you can easily disassemble. Many brands participate in closed-loop recycling programs, helping you reduce waste.

What is the difference between heat pump dryers and traditional dryers?

You see heat pump dryers use a closed-loop system to move heat efficiently. Traditional dryers rely on electric coils or gas. Heat pump models cut energy use by up to 65%. You enjoy lower utility bills and faster drying times.

How long do advanced heating elements typically last?

You expect longer lifespans with new materials and designs. Ceramic and composite elements resist wear and thermal shock. Brands like Maytag and Samsung offer heating elements that last 10 to 15 years. You replace them less often and save money.

Do smart dryers connect to home automation systems?

You integrate smart dryers with home automation platforms. You control cycles, monitor energy use, and receive maintenance alerts through apps or voice assistants. This connectivity streamlines your laundry routine and improves convenience.

Tip: Always check compatibility with your home automation system before purchasing a smart dryer.

| Feature | Benefit to You |

|---|---|

| Smart Controls | Automated performance |

| Modular Design | Easy recycling |

| Safety Sensors | Enhanced protection |